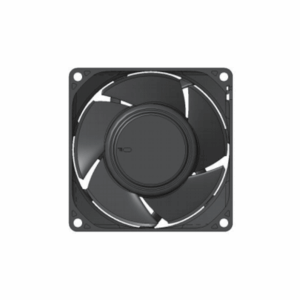

120mm DC Axial Fan Brushless High-Performance

This high-performance 120mm brushless DC fan provides powerful cooling. Operating at 12V, it delivers impressive airflow up to 77.30 CFM. It features PWM for precise speed control, auto-restart protection, and is made from durable UL 94V-0 thermoplastic. Ideal for demanding applications.

High-Performance 120mm Brushless Cooling DC Axial Fan: Power, Accuracy, and Security

Worldwide of innovative electronic devices and high-power machinery, effective thermal management is not simply a suggestion; it’s an important need. As elements end up being more effective and small, the warmth they create can deteriorate efficiency and shorten their lifespan.

This 120mm brushless DC axial fan is crafted to fulfill these obstacles head-on, delivering an effective air conditioning service that incorporates robust performance, smart control, and integrated safeguards for supreme reliability. Made for requiring applications where failure is not an option, this DC axial fan is the perfect choice for whatever from high-performance computer and server racks to commercial control cabinets and sophisticated electronics.

Unmatched Air Conditioning Performance .

At the core of this DC axial fan’s style is its capacity to relocate a substantial volume of air with impressive force. It boasts 2 distinctive efficiency designs to accommodate different air conditioning needs. The high-speed design is a true giant, rotating at 2300 RPM to create an excellent air flow of 77.30 cubic feet per minute (CFM). This high CFM score is essential for applications that require to dissipate a large amount of heat promptly, making sure that parts remain within their optimum operating temperature levels even under hefty lots.

Matching its high air movement is a solid fixed stress of 0.13 inchH2O (3.25 mmH2O). Fixed stress is a measure of the fan’s ability to press air via obstacles like thick heatsinks, radiators, and restrictive grilles. This makes the high-speed model especially reliable in tightly loaded enclosures where air movement is hindered. For applications where sound levels and power intake are a better worry, a 2nd design runs at a quieter 1700 RPM. This variant still provides an extremely commendable 57.31 CFM of air flow and 0.06 inchH2O (1.60 mmH2O) of static stress, offering a well balanced remedy that does not compromise too heavily on cooling down power.

The Brushless DC Motor Advantage .

The heart of this DC axial fan is its sophisticated brushless DC (BLDC) motor. Unlike traditional DC motors that rely on physical brushes to move power, brushless motors utilize digital commutation. This modern layout eliminates the rubbing and wear related to brushes, bring about a host of benefits.

Primarily is a significantly longer lifespan and greater dependability. Without brushes to break, the electric motor is less vulnerable to failing and requires essentially no maintenance, an essential advantage in commercial or server atmospheres where downtime can be costly.

The lack of brush friction additionally indicates the electric motor runs much quieter and generates less of its own warmth, contributing to total system effectiveness. This performance equates directly into lower power intake; the high-speed model eats simply 3.84 watts, while the extra moderate variation utilizes an even reduced 2.16 watts. This power efficiency is not only environmentally friendly but also decreases operational expenses over the long-term.

Intelligent Control with Pulse Size Modulation (PWM) .

This DC axial fan is equipped with Pulse Size Modulation (PWM) modern technology, using accurate and dynamic rate control. Instead of going for a consistent, set rate, PWM permits the fan’s rate to be changed in real-time based upon the system’s thermal requirements. A specialized fourth cable receives a signal that rapidly cycles the electric motor’s power on and off. The “task cycle,” or the portion of time the signal is on, identifies the fan’s speed.

This intelligent control has several vital advantages. It permits an ideal equilibrium between cooling efficiency and noise. When the system is still or under a light tons, the DC axial fan can be reduced, substantially minimizing sound and power intake. As the temperature level increases throughout extensive jobs, the follower speed can be ramped up to give optimal cooling. This flexible air conditioning not just develops a quieter user experience but also extends the fan’s life-span by minimizing unnecessary deterioration.

Developed for Longevity and Safety and security .

Reliability is even more boosted by a suite of safety features. The DC axial fan’s frame and impeller are created from a top quality thermoplastic that meets the UL 94V-0 flammability criterion. This is the highest possible ranking for plastics, implying the material will certainly self-extinguish within 10 seconds of a fire being eliminated and won’t trickle flaming bits, offering a crucial safety measure in any digital device.

The electric motor itself is impedance safeguarded, which safeguards it from damages as a result of overheating in a stall condition. In addition, an incorporated Auto-Restart feature gives a necessary layer of defense. If the DC axial fan blades are temporarily blocked by an outside item, the motor’s inner circuit will instantly reduce power to stop a present overload that can stress out the motor. When the obstruction is eliminated, the fan will immediately attempt to reboot, guaranteeing continual operation without hand-operated intervention.

Another critical safety and security attribute is Reverse Polarity Security . This avoids damage to the follower’s sensitive electronic devices if the power cables are mistakenly linked improperly. A straightforward mistake during installation could or else ruin the fan, yet this attribute guarantees the follower stays risk-free and useful.

Advanced Surveillance and System Integration .

For sophisticated system management, the DC axial fan consists of an FG (Frequency Generator) signal output. This is a responses signal that gives a square wave pulse, with the frequency being directly symmetrical to the DC axial fan’s rotational speed. System managers and control systems can monitor this FG signal to obtain a real-time analysis of the fan’s RPM. This enables precise verification that the fan is operating as anticipated and can be utilized to set off alarm systems or informs if a fan fails or its speed drops listed below a critical threshold.

The DC axial fan is created to operate reliably across a wide range of environmental problems, with an operating temperature series of -10 ° C to 70 ° C and a storage temperature series of -40 ° C to 80 ° C. This effectiveness makes certain regular performance whether it’s made use of in a climate-controlled information facility or a much more difficult industrial setup.

In summary, this 120mm brushless DC axial fan is greater than just an air conditioning part; it’s an extensive thermal management option. It integrates the raw power of high air movement and fixed pressure with the knowledge of PWM control and the integrity of a brushless motor.

With its durable, flame-retardant construction and a full collection of electronic protections, it is engineered for long life and security in the most requiring applications. Whether you are building a high-end gaming computer, a resilient web server range, or advanced commercial equipment, this follower provides the efficiency, control, and peace of mind you require.