Summary

How the Right Fan Can Improve 3D Printing refers to the critical role of cooling fans in enhancing the performance and quality of 3D printed objects. In 3D printing, the cooling process significantly affects material properties, layer adhesion, and the overall success of a print.

The selection and configuration of cooling fans can make a substantial difference, influencing factors such as print speed, detail, and the risk of common printing issues like warping or stringing. Given the increasing popularity of 3D printing across various industries—from hobbyist to professional applications—the appropriate use of fans has become a focal point in optimizing printing efficiency and output quality.

Different types of cooling fans, including axial, radial (blower), and cross flow fans, serve distinct purposes within the 3D printing process. Axial fans are favored for general airflow and cooling of electronic components, while radial fans excel in focused part cooling due to their ability to produce high-pressure airflow. The correct choice of fan type, alongside thoughtful fan placement and speed configuration, is essential for achieving desired print characteristics.

Notably, the impact of fan operation extends beyond simple cooling; it directly correlates with material-specific requirements and print complexities. For instance, materials like PLA benefit from rapid cooling, while others such as ABS require more careful temperature management to avoid deformation. Misconfiguration can lead to significant printing issues, making the understanding of fan dynamics vital for users seeking optimal results.

Controversies in fan usage often revolve around the balance of cooling—too much or too little can both lead to defects in printed objects. Properly tuning fan speeds and placement based on the specific materials and designs can mitigate these risks.

As 3D printing technology evolves, the importance of fan selection and management continues to gain recognition, marking it as a crucial consideration for both new and experienced users in the field.

Table of Contents

Types of Fans Used in 3D Printing

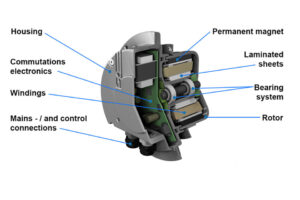

In the realm of 3D printing, the choice of cooling fans is crucial for optimal performance and print quality. There are three primary types of fans utilized in 3D printers: axial fans, radial (blower) fans, and cross flow fans.

Axial Fans

Axial fans are the most common type of fan found in 3D printers. These fans operate by pushing air in a direction parallel to the fan blade axis, which results in high-volume airflow at low pressure. They are particularly effective for cooling the hotend (heatsink), ventilating the mainboard, and ensuring general airflow within the printer enclosure.

Axial fans are available in various sizes and voltages, commonly found in both 12V and 24V DC configurations, allowing compatibility with a wide range of 3D printer models from hobbyist to industrial.

Radial (Blower) Fans

Radial fans, also known as blower fans, are designed to provide concentrated airflow and are particularly suitable for part cooling. They operate by sucking air in from the center and expelling it outwards, creating high-pressure airflow which is beneficial for cooling extruded filament rapidly.

Radial fans are advantageous in focused cooling applications where precise airflow is necessary, making them ideal for components that require higher pressure to receive effective cooling. Like axial fans, they are also available in 12V and 24V versions, catering to both consumer and professional needs.

Impact of Fan Placement and Configuration

Types of Cooling Fans

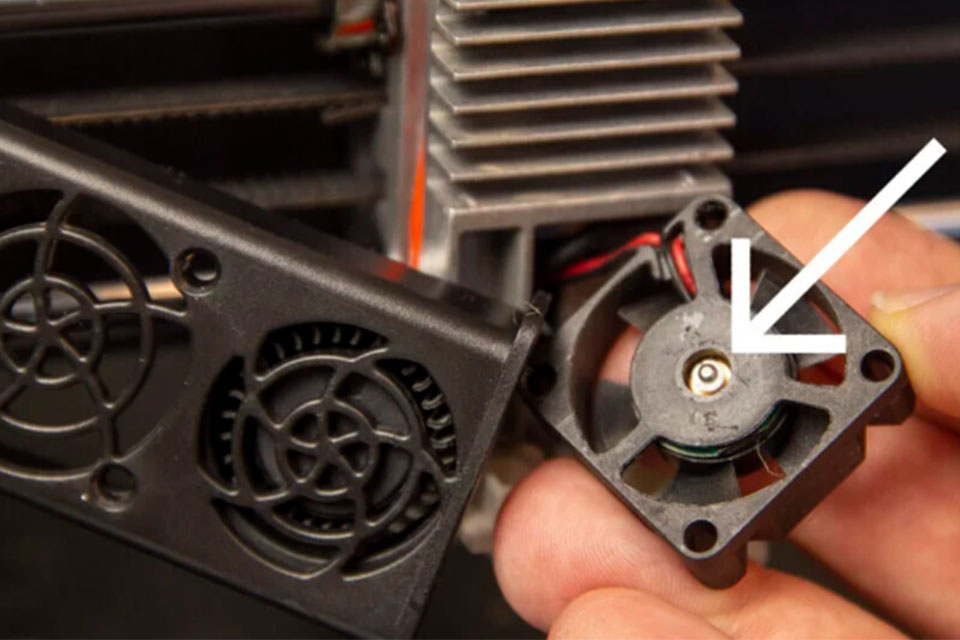

Cooling fans in 3D printing can primarily be categorized into two types: layer fans and hotend fans. Layer fans, also known as part cooling fans, play a crucial role in cooling freshly extruded plastic. They help solidify the material quickly, which is essential for achieving sharp details, preventing sagging in overhangs, and successful bridging in prints.

Hotend fans, on the other hand, maintain the extrusion temperature of the filament by preventing heat from rising too high in the hotend, which can cause clogs and extrusion issues.

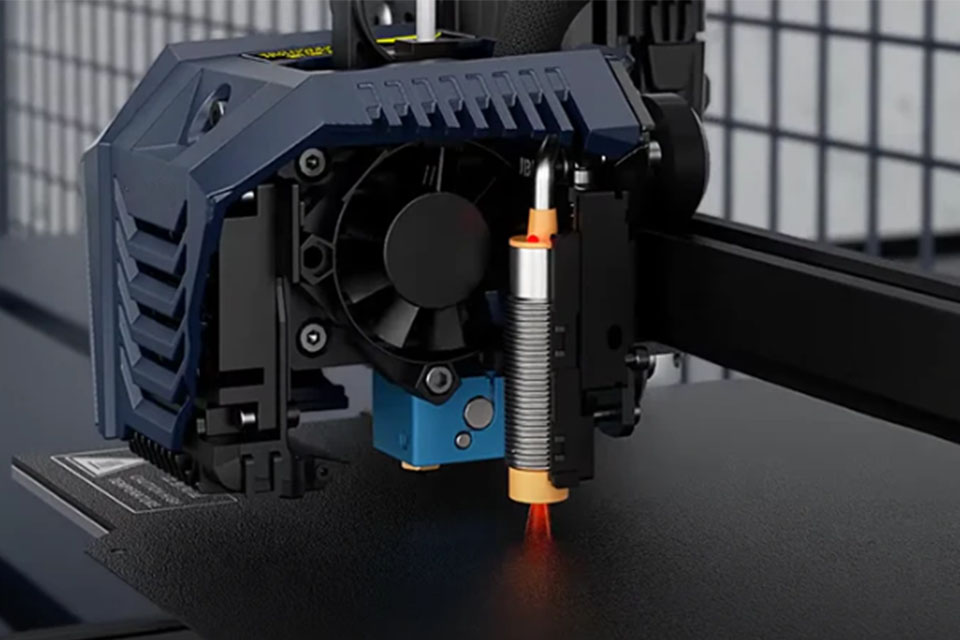

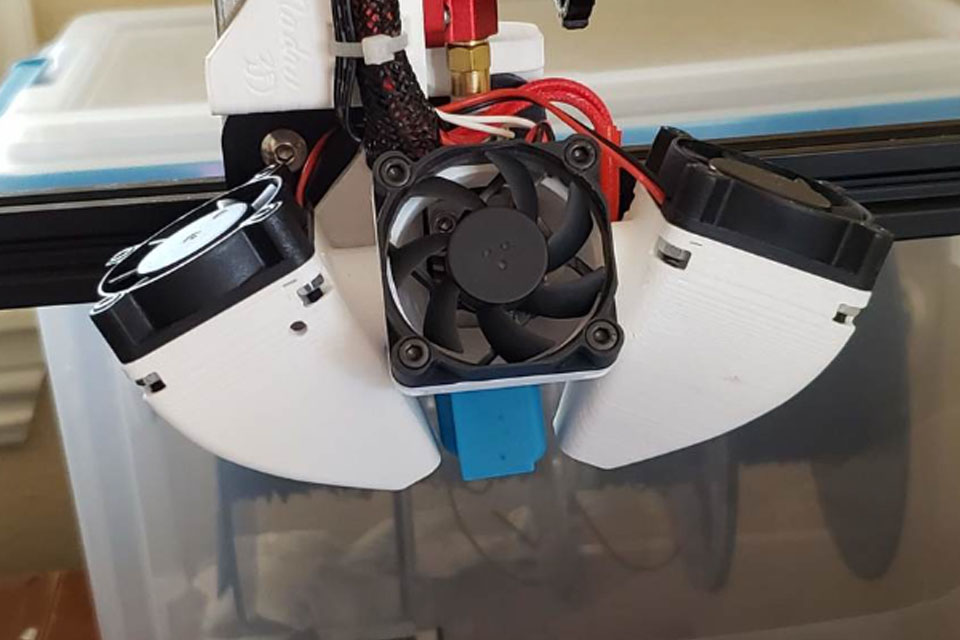

Fan Placement

The placement of fans is critical for optimizing cooling performance. Proper positioning ensures that the air is directed efficiently at the printed layers, enhancing solidification and preventing warping. For example, a well-placed layer fan can blow air directly onto the freshly deposited plastic, allowing it to cool evenly. However, it is essential to avoid configurations that might lead to excessive cooling, which could negatively impact the print quality.

Configurable Fan Settings

Various configurable fan settings can be utilized to improve printing outcomes. Options include adjusting the fan speed, setting initial fan speed, and configuring fan operation at specific print heights. For instance, enabling fans at certain heights can be particularly beneficial when working with multi-material printers, as different filaments may have distinct cooling requirements. Furthermore, specialized settings can allow fans to operate only during the creation of rafts, brims, or supports, optimizing cooling where needed without affecting other parts of the print.

Material-Specific Considerations

Different materials also dictate specific cooling strategies. For example, PLA typically benefits from consistent layer cooling, while ABS may require reduced fan usage to prevent cracking due to rapid cooling. Understanding the interactions between material properties and cooling requirements is essential for achieving optimal print results.

Optimal Fan Speeds

Optimal fan speeds play a critical role in achieving high-quality 3D prints, influencing factors such as material adhesion and cooling efficiency. The fan speed in 3D printing is defined as the rate at which the cooling fans on the printer’s toolhead operate, typically represented as a percentage of the maximum fan capabilities.

Initial and Regular Fan Speeds

During the printing process, the fan speed transitions from an Initial Fan Speed to a Regular Fan Speed based on user-defined settings. For example, if the Initial Fan Speed is set to 0% and the Regular Fan Speed to 100% at the sixth layer, the fan will gradually increase from 0% to 100% throughout the first six layers. This gradual increase helps maintain the necessary thermal conditions for optimal adhesion during the initial layers of the print. Lower Initial Fan Speeds improve material adhesion to the build plate by allowing the material to cool more slowly, thereby preventing warping and ensuring that the print remains securely attached.

Material-Specific Fan Speed Settings

Different materials require different cooling strategies, and as such, Luban software provides tailored material settings that include print temperature, bed temperature, and cooling parameters for various filaments like PLA, ABS, and PETG. While a normal fan speed of 0% is generally recommended to enhance layer adhesion, higher fan speeds may be necessary for prints with intricate details, as they help to solidify the material quickly and maintain precision.

Adjusting Fan Speed for Layer Times

The fan speed can also be adjusted based on the layer time. For layers with longer print times (e.g., 20 seconds or more), a linear increase in fan speed from 70% to 100% can be implemented to ensure proper cooling without affecting layer adhesion. Such adjustments help in optimizing the cooling of the filament, which is crucial for maintaining the integrity and quality of the print.

Best Practices for Fan Speed Settings

To achieve optimal printing results, it is advised to experiment with fan speed settings based on specific materials and model complexities. Users are encouraged to refer to community best practices and manufacturer recommendations for optimal configurations. Finding the right balance between fan speed and other parameters can enhance print quality while reducing common issues such as stringing and poor surface finishes.

Benefits of Using the Right Fan

Using the appropriate fan in a 3D printer can significantly enhance the overall printing quality and efficiency. The effectiveness of a fan is largely determined by its configuration and the user’s specific printing needs, as different settings can lead to varying results in the final printed object.

Improved Cooling

One of the primary benefits of using the right fan is improved cooling of the printed layers. Effective cooling helps solidify the filament quickly, reducing the likelihood of issues such as warping and stringing. For instance, higher fan speeds can allow for quicker cooling of the print head and the printed material, leading to better layer adhesion and overall structural integrity.

Enhanced Print Quality

Proper fan usage directly impacts print quality. With the correct fan setup, users can achieve more precise layer definitions, smoother surfaces, and stronger prints. For intricate designs, a well-calibrated cooling fan can prevent overheating of the filament, which might otherwise lead to poor extrusion and surface imperfections. This careful balance between speed and cooling is crucial for achieving high-quality prints, especially with complex geometries.

Flexibility in Material Usage

Different materials have unique cooling requirements; thus, using the appropriate fan allows for a wider range of filaments to be printed successfully. For example, materials that require rapid cooling, such as PLA, benefit from high airflow, while others like TPU may need slower speeds to avoid defects. Understanding the strengths and ideal use cases for each fan type—such as axial or radial fans—enables users to tailor their setup to suit specific materials and print conditions, maximizing performance and efficiency.

Prevention of Common Printing Issues

A well-functioning fan can also help mitigate common printing problems. For example, under-extrusion can occur when a fan fails to provide adequate cooling, leading to weak layers that may easily break apart. By ensuring that the fan operates effectively, users can reduce the incidence of such issues, ultimately saving time and material costs associated with reprinting flawed objects.

Common Issues and Solutions

3D printing is a nuanced process that can be influenced by various factors, particularly cooling, temperature settings, and adhesion. Understanding common issues and their solutions can enhance the quality of printed objects.

Cooling Issues

Cooling is vital for achieving quality prints, especially with materials susceptible to warping or deformation.

- Brittle Parts and Poor Layer Adhesion: Excessive cooling can make parts brittle or lead to inadequate bonding between layers, resulting in structural weaknesses.

- Deformation and Warping: Insufficient cooling may cause materials like ABS to warp, necessitating careful cooling strategies, including the use of heated enclosures to maintain stable temperatures.

Solutions

- Adjust Fan Speed: The fan speed can be modified, typically ranging from 0 to 100%, to optimize cooling rates for different materials. For instance, PLA benefits from higher cooling speeds, while ABS requires moderated cooling to prevent deformation.

- Experiment with Layer Height and Resolution: Higher resolutions and smaller layer heights can improve surface finish and detail but may require longer cooling times. Balancing these parameters is essential to achieve the desired print quality.

Adhesion Problems

Bed adhesion is a frequent challenge in 3D printing, where prints may detach during the process or adhere too strongly to the bed, complicating removal.

Solutions

- Use Adhesion Assistants: Techniques such as applying a glue stick or blue tape on the print bed can enhance adhesion, ensuring prints remain securely in place during printing.

- Modify Bed Temperature: Maintaining an appropriate bed temperature can help prevent warping and improve adhesion, particularly for materials like PETG and PC.

Temperature Control

Improper temperature settings can lead to various issues, including:

- Under-Extrusion: If the filament does not melt sufficiently due to low temperatures, it may cause clogging or poor material flow.

- Over-Extrusion: Conversely, excessive temperature can result in over-extrusion, leading to blobs and a rough surface.

Solutions

- Tune Nozzle Temperature: Careful adjustments to the nozzle temperature are crucial for different materials. For example, PC requires higher temperatures (260°C to 310°C) for optimal printing results.

- Monitor Print Speed: Adjusting the print speed in conjunction with temperature can help prevent sagging in overhangs and loss of detail in smaller features.

By addressing these common issues with effective solutions, users can significantly improve their 3D printing outcomes, achieving better quality and more reliable results.

Energy Consumption and Efficiency

Energy efficiency is a crucial aspect of 3D printing that can significantly impact operational costs and environmental sustainability. Research indicates that optimizing the insulation of the hot end in 3D printers can lead to a reduction in energy consumption by approximately 30.63% to 33.8%. Furthermore, innovative cooling methods have been shown to reduce total power consumption by around 23% when compared to existing commercial devices.

The choice of fan type also plays a critical role in energy efficiency. Radial fans, known for their ability to generate high-pressure airflow, are often more effective in focused cooling applications than axial fans, which are designed to move larger volumes of air at lower pressures. While axial fans may suffice in many situations, they are generally less efficient in applications requiring concentrated airflow, which can result in higher overall energy consumption.

Additionally, the configuration and placement of fans can influence both cooling performance and energy usage. When optimizing fan settings, such as speed adjustments in filament settings, users can further enhance the efficiency of their printers without needing significant modifications. It is important to consider that while fans contribute to cooling critical components like the power supply and control board, their impact on the overall efficiency of the 3D printing process should not be underestimated.