Summary

The role of bearings in fan longevity, specifically comparing ball bearings and sleeve bearings, is a critical consideration in mechanical engineering and design. Bearings are essential components that facilitate smooth motion in machinery, affecting performance, efficiency, and lifespan.

Ball bearing fans consist of small metal balls that allow for low friction and high-speed rotation, making them ideal for applications requiring durability and precision. In contrast, sleeve bearings, or plain bearings, use a sliding surface and are often less costly, though they generally provide shorter lifespans and require more maintenance in demanding environments.

The distinction between these two bearing types is particularly significant in fan applications, where operational demands can vary widely. Ball bearing fans typically offer longer service life and greater resistance to wear, with estimates of up to 70,000 hours under optimal conditions, while sleeve bearings may only last 3 to 4 years in continuous use. The choice between the two often hinges on factors such as load capacity, speed, and operational environment, leading to ongoing debates among engineers regarding the best bearing type for specific applications.

Controversies surrounding bearing selection often arise from the trade-offs between initial costs and long-term performance. Although ball bearing fans tend to be more expensive initially, their reduced maintenance needs and extended lifespans can result in lower total costs over time, making them a preferred choice for high-speed, high-load scenarios. Conversely, while sleeve bearings are more economical upfront, their susceptibility to failure and increased maintenance requirements in demanding applications raise questions about their long-term viability.

Ultimately, understanding the implications of bearing selection is crucial for ensuring fan longevity and efficiency. Both types have their unique advantages and disadvantages, necessitating careful evaluation by engineers and designers based on specific operational requirements, environmental conditions, and maintenance capabilities.

Table of Contents

Types of Bearings

Overview of Bearings

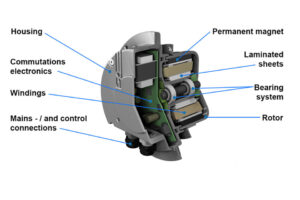

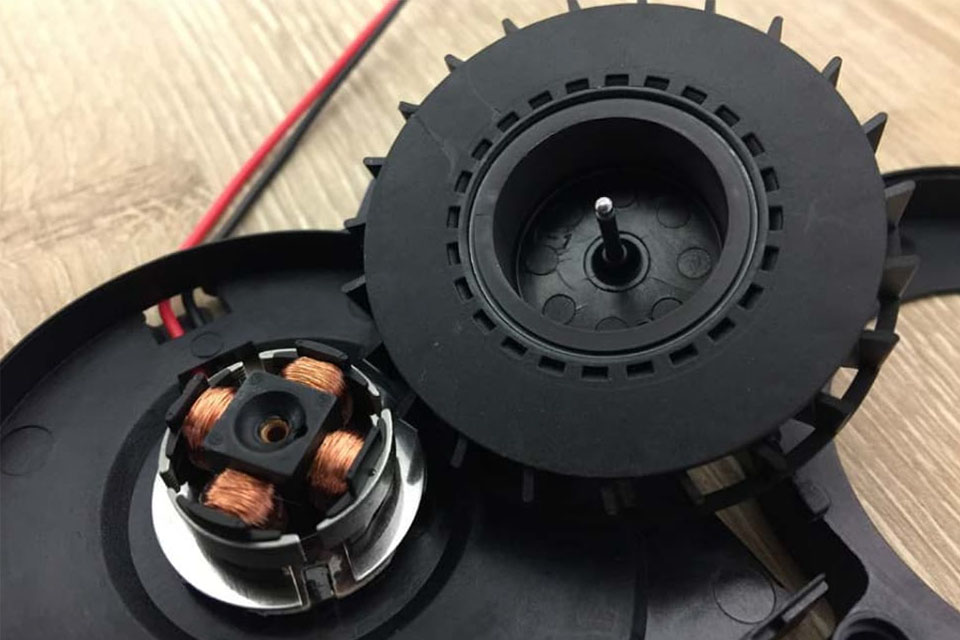

Bearings are essential mechanical components that facilitate smooth motion in various machinery by enabling rotational or linear movement with minimal friction. They are categorized primarily into two main types: rolling bearings and sliding bearings, each designed for specific applications and performance requirements.

Comparison of Ball Bearing fans and Sleeve Bearing fans

Both ball bearing fans and sleeve bearing fans have distinct advantages and disadvantages that make them suitable for different applications. Ball bearing fans tend to have a higher initial cost but offer greater longevity and lower maintenance needs, making them preferable in high-speed scenarios.

In contrast, sleeve bearing fans are generally less expensive but may require more frequent replacement, especially under high operational temperatures. Engineers must carefully consider factors such as load capacity, operating life, and lubrication requirements when selecting the appropriate type of bearing for a specific application.

Performance Comparison

When evaluating the performance of ball bearing fans and sleeve bearing fans in fan applications, several key factors must be considered, including load capacity, speed capabilities, and durability.

Load Capacity

Load capacity is crucial when selecting a bearing type for specific applications. Sleeve bearings typically possess a higher load capacity due to the larger contact area between the shaft and the bearing surface, making them suitable for heavy-duty applications that involve significant loads or impacts.

Conversely, ball bearing fans are better suited for lighter loads, as their rolling motion reduces friction, allowing for smoother operation in high-speed rotations with minimal load. This difference means that while sleeve bearings excel in scenarios demanding strength, ball bearings are preferable in applications requiring efficiency and speed.

Speed and Friction

The speed at which the machinery operates significantly influences bearing performance and lifespan. Ball bearing fans generally outperform sleeve bearings at higher rotational speeds due to their lower friction coefficient, which results from their rolling motion.

Sleeve bearing fans exhibit higher friction because of their sliding contact, which can lead to increased wear and energy consumption in high-speed applications. Therefore, in scenarios requiring high performance and precision, ball bearings are often more suitable, while sleeve bearings may be better for applications with lower speeds and heavier loads.

Durability and Longevity

The longevity of bearings is also affected by their design and construction. High-quality ball bearings can provide a useful life of approximately 60,000 to 70,000 hours under normal operating conditions. In contrast, sleeve bearings, while cheaper upfront, often have shorter lifespans compared to ball bearings.

Factors such as workload and usage patterns also impact durability; for instance, fans operating continuously at high speeds are more likely to wear out faster. Proper maintenance of both types of bearings is essential for maximizing their operational lifespan and efficiency.

Impact on Fan Longevity

The longevity of a fan is significantly influenced by the type of bearing used, as well as various operational and environmental factors. Bearings serve as crucial components in fans, affecting both their performance and lifespan.

Bearing Types and Their Effects

Ball Bearing fans

Ball bearings Fans typically have a lifespan of around 50,000 hours under optimal conditions, making them a preferred choice for applications requiring reliable cooling in densely packed electronic systems.

When operating temperatures are kept between 25° and 60° C, ball bearing fans can maintain this longevity, although their performance begins to degrade significantly when temperatures exceed 70° C. The dual ball bearing configuration is especially beneficial for systems generating substantial heat, as it can offer up to double the lifespan compared to other bearing types.

Sleeve Bearing fans

In contrast, sleeve bearings are generally less robust and have shorter lifespans. While they can be less expensive and suitable for low-load applications, they tend to fail sooner, with approximately 90% of sleeve bearing fans expected to be operational after 3 to 4 years of continuous use.

Sleeve bearings may provide comparable lifespans to ball bearings in vertical orientations, yet they are still vulnerable to external conditions such as shock loading and contamination. Thus, their longevity is often compromised in demanding environments.

Operational and Environmental Influences

Usage Patterns

The intensity and manner in which fans are used greatly affect their service life. Fans that operate continuously at high speeds or carry heavy loads experience more wear and tear, leading to reduced lifespans. It is crucial to select fans designed for specific operational requirements to ensure longevity.

Environmental Conditions

External factors such as vibrations, humidity, and temperature fluctuations also play a critical role in fan longevity. Environments with high humidity and temperature extremes can shorten the lifespan of both ball bearing fans and sleeve bearing fans by increasing wear on components and degrading lubricants. Regular maintenance practices, including proper lubrication and cleaning, can mitigate some of these environmental impacts and enhance the reliability of fan bearings.

Common Installation Mistakes

Improper installation of bearings can lead to significant performance issues and premature failures.

Inadequate Lubrication

Proper lubrication is critical for the longevity of bearings. Insufficient lubrication can cause the shaft and the bearing to rub against each other, generating excessive heat and resulting in damage. Regular checks of lubricant levels, as well as ensuring the right type and amount of lubricant is used, can help avoid these issues. Over-lubrication can also be detrimental, potentially leading to overheating of the lubricant and subsequent bearing failure.

Incorrect Clearances

One of the most prevalent causes of bearing failure is the complete elimination of clearances at the time of installation. This can result in overheating and increased wear on the bearing components, leading to catastrophic failure. It is essential to maintain appropriate clearances as specified by the manufacturer to ensure optimal bearing operation.

Failure to Follow Installation Procedures

Adhering to the manufacturer’s installation guidelines is crucial. Neglecting these recommendations can result in improper fitment and alignment, which may cause vibrations and increase the risk of mechanical defects. Regular maintenance, including re-checking alignment after any significant maintenance activities, is vital for maintaining bearing integrity.

Poor Quality Components

The choice of bearing suppliers can greatly influence the quality and reliability of the installed components. Selecting bearings from reputable suppliers can help avoid issues associated with substandard materials and manufacturing processes, which may not withstand operational stresses.

Ignoring Environmental Factors

External conditions, such as corrosion or contamination from foreign materials, can significantly impact bearing performance. Ensuring that the installation area is clean and free from contaminants is essential for prolonging bearing life. Additionally, attention should be paid to the environmental conditions, such as temperature and humidity, to select the appropriate type of bearing for specific applications.

By avoiding these common installation mistakes, users can enhance the performance and reliability of both ball bearing fans and sleeve bearing fans, ultimately contributing to the longevity of fan systems and reducing the need for frequent repairs or replacements.

Maintenance Practices

Proper maintenance of bearings is essential for ensuring their optimal performance and extending their lifespan, particularly for both ball and sleeve bearings. Regular maintenance practices such as lubrication, cleaning, and inspection are critical to preventing premature bearing failure and maximizing operational efficiency.

Key Maintenance Practices

Lubrication

Lubrication plays a pivotal role in reducing friction and wear between the moving parts of the bearing. Proper lubrication not only minimizes heat generation but also helps to protect against corrosion and contamination. It is essential to use the appropriate type of lubricant based on the bearing’s operating conditions and specifications.

Environmental Control

Maintaining a clean operating environment is vital for the longevity of sleeve bearings. Dust, dirt, and moisture can lead to significant wear and potential failure. Implementing protective measures such as seals or covers can prevent contaminants from entering the bearings. Moreover, controlling temperature and humidity levels within the working environment helps mitigate corrosion and enhances bearing life.

Regular Inspections

Routine inspections are necessary to identify early signs of wear or damage. Regular checks allow maintenance personnel to detect issues such as misalignment or lubrication deficiencies before they escalate into more significant problems. Scheduled maintenance checks are crucial in preventing costly downtimes and ensuring that machinery operates smoothly and efficiently.

Installation Best Practices

The initial installation of bearings is equally important as ongoing maintenance. Incorrect installation can lead to misalignment and premature wear. Following manufacturer guidelines for correct fitting is essential to ensure optimal performance from the outset. Maintenance staff should be equipped with best practice guides and training to perform installations and maintenance correctly.

By prioritizing these maintenance practices, businesses can significantly reduce the risk of bearing failure and ensure the reliable operation of their machinery, ultimately enhancing the longevity of their bearings and associated equipment.