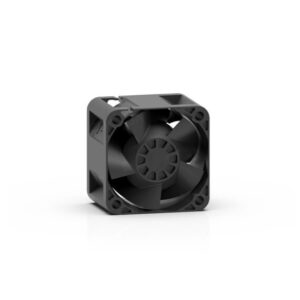

Engineered DC Axial Fan for Consistence and Airflow

Experience powerful cooling with our high-speed 30x30x10mm DC axial fan. Delivering up to 4.22 CFM at 13,000 RPM, it ensures consistent, superior airflow for compact electronics. Features PWM control, multiple protection options, and a long service life for ultimate reliability.

In the ever-evolving landscape of contemporary electronic devices and industrial machinery, reliable thermal administration is not just a function– it’s an essential need. The boosting power density of elements, coupled with the fad in the direction of miniaturization, provides a significant design obstacle: dissipating warmth successfully and dependably to guarantee ideal efficiency, avoid early failing, and expand the functional life of valuable equipment.

Addressing this crucial requirement head-on, the series is an engineered DC axial fan that supplies constant, high-performance airflow in an incredibly compact and durable plan. Determining simply 40x40x10mm, this DC axial fan is thoroughly made to give superior cooling options for a substantial selection of applications where space is at a premium however thermal stability can not be endangered.

Engineered for Peak Performance and Unwavering Consistency .

At the heart of the Series lies a technically advanced brushless DC electric motor, a core part that establishes it apart in regards to effectiveness, durability, and control. Unlike their air conditioning equivalents, brushless DC motors provide significantly reduced power consumption, contributing to energy savings and lowered operational expenses over the fan’s life-span.

The fundamental layout of DC electric motors allows for specific speed control, enabling system designers to tailor the cooling efficiency to the specific, dynamic needs of their application. This follower operates on the principle of axial flow, where the uniquely made impeller blades draw air in and discharge it parallel to the follower’s motor axis, developing a straight and effective stream of cooling down air.

The performance capabilities of the DC axial fan are plainly highlighted in its thorough air efficiency requirements. The DC axial fan is readily available in numerous designs, each enhanced for a different rotational speed– 6500, 7500, and 8000 RPM– to offer a range of cooling down alternatives. This allows designers to make a precise trade-off in between air flow, static stress, and acoustic sound. As an example, the DC axial fan designs, running at 6500 RPM, supply a decent 7.24 CFM of airflow with a maximum static pressure of 4.7 mmH ₂ O, all while preserving a low sound account of 28.6 dB( A).

At the various other end of the range, the high-speed GD4010H models rotate at 8000 RPM to create a powerful 11.29 CFM of airflow and a fixed stress of 6.49 mmH ₂ O, making them perfect for largely jam-packed electronic devices or systems with high insusceptibility to airflow. This adaptability guarantees that whether the top priority is near-silent operation for office equipment or maximum warm dissipation for commercial controls, there is a GD4010 model flawlessly fit for the job.

Durable Building for Unmatched Durability and Security .

The reliability of a DC axial fan is directly tied to the quality of its building and construction and the products used. The DC axial fan is built to last, with both its frame and impeller crafted from Thermoplastic PBT (Polybutylene Terephthalate). This durable engineering plastic is renowned for its exceptional mechanical toughness, high stiffness, and amazing dimensional security, guaranteeing the follower preserves its precise shape and function even under mechanical anxiety. Moreover, PBT supplies superior resistance to a wide variety of chemicals, consisting of oils and solvents, making it ideal for release in tough commercial environments.

Crucially, the PBT material utilized in the series is rated UL 94V-0. This is the greatest ranking for fire retardancy under the UL 94 conventional, suggesting that the product will self-extinguish within 10 seconds after a fire is eliminated from a vertical specimen which no flaming drips are produced. This safety certification is extremely important in electronic applications, supplying a crucial layer of defense and decreasing fire danger within encased systems.

A crucial element figuring out a follower’s life expectancy and dependability is its bearing system. Recognizing that various applications have different needs, the DC axial fan is supplied with two distinct bearing options:.

- Round Bearing System: For applications demanding the utmost in long life and efficiency, the sphere bearing option is the top option. It uses an exceptional life span of 70,000 hours at an operating temperature of 40 ° C, comparable to virtually 8 years of constant operation. Sphere bearings include rolling rubbing, which is much more effective and sturdy than the sliding friction of sleeve bearings.

This layout supplies a broader operating temperature range, from a frigid -30 ° C to a hot 70 ° C, making it ideal for gadgets that experience considerable temperature level variations. A major benefit of sphere bearings is their capacity to be mounted in any orientation– upright, horizontal, or at an angle– without a considerable decline in life expectancy, offering maximum adaptability in system layout.

- Sleeve Bearing System: The sleeve bearing alternative offers a dependable and affordable solution for applications with less rigid life expectancy requirements. It provides a service life of 30,000 hours at 40 ° C and is known for its quieter procedure, specifically at lower speeds, which can be an essential factor in noise-sensitive atmospheres like home or office electronics. While finest matched for vertical mounting to make sure correct lubrication and longevity, the sleeve bearing variation of the collection is a superb selection for budget-conscious tasks that still need reputable air conditioning efficiency.

Flexibility Via Modification and Intelligent Control .

The DC axial fan is not a one-size-fits-all component but a flexible system for air conditioning. It is readily available in a range of versions that support numerous input voltages, consisting of 5V, 12V, and 24V DC, making it simple to incorporate into a wide variety of electrical systems. Power intake is enhanced across the range, from as reduced as 1 watt on the 5V version to 2.28 watts on the high-performance 12V version.

Beyond the typical specifications, the DC axial fan can be outfitted with a suite of available functions to improve system knowledge and protection. Electric motor security choices like Reverse Polarity (RP), Vehicle Begin (AS), and Over Voltage Protection (OVP) secure the fan from prospective electrical faults. For system tracking and control, a selection of signal outputs are available. The Frequency Generator (FG) output offers a signal proportional to the fan’s rotational speed, permitting the host system to keep track of for appropriate operation.

Rate control modes, such as Pulse Size Inflection (PWM), enable the system to dynamically adjust the follower’s rate in real-time, creating an intelligent air conditioning system that offers high performance when needed and runs quietly and effectively under normal problems.

The Perfect Choice for a Plethora of Applications .

Finally, the series DC Axial Fan is a remarkable cooling solution engineered for uniformity, dependability, and efficiency. Its mix of a compact 40x40x10mm frame, powerful brushless DC electric motor, resilient and flame-retardant PBT building, and the choice of a long-life sphere bearing or silent sleeve bearing system makes it extremely functional. The vast array of readily available versions and adjustable attributes makes certain that system developers can choose the perfect fan for their particular demands.

The collection is preferably matched for a broad spectrum of applications, consisting of:.

- Compact Electronics and Embedded Equipments: Cooling single-board computer systems like the Raspberry Pi, or various other largely packed digital modules.

- Telecommunications Equipment: Ensuring the integrity of routers, switches, and various other network equipment.

- Industrial Controls: Dissipating warmth from PLCs, motor drives, and power products in control cupboards.

- Medical Gadgets: Supplying quiet and reliable air conditioning for analysis and surveillance tools.

- 3D Printers and Prototyping Devices: Cooling down extruders and electronic elements to make sure print high quality.

- Server and Storage Solutions: Spot cooling for details elements within bigger systems.

When efficient thermal administration is essential and room is limited, our DC axial fan sticks out as the conclusive choice, providing constant airflow and comfort.