Summary

Electronically Commutated (EC) fans are advanced motor-driven fans that utilize brushless DC motor technology, offering enhanced energy efficiency and operational flexibility compared to traditional Alternating Current (AC) fans. Notable for their ability to operate at efficiencies exceeding 90%, EC fans consume up to 70% less power, making them a popular choice across various applications including HVAC systems, data centers, refrigeration, and automotive industries. Their design allows for precise speed control, resulting in significant energy savings and lower operational costs, aligning with global trends toward sustainability and energy conservation.

The versatility of EC fans is evident in their multiple configurations, including axial, centrifugal, integrated, and specialty designs, each tailored for specific performance requirements. Axial EC fans excel in high airflow applications, while centrifugal models generate higher static pressure, making them suitable for environments with airflow resistance. Integrated EC fans are commonly found in refrigeration units, optimizing space and efficiency, while specialty fans cater to unique demands such as explosion-proof environments.

In addition to energy savings, EC axial fans are recognized for their longevity and reliability, with lifespans that can reach 70,000 hours, significantly outpacing traditional AC fans which typically last around 10,000 hours. This durability reduces maintenance costs, as the simpler design of EC axial fans leads to fewer component failures and lower long-term expenses. The growing adoption of EC axial fan technology reflects the increasing regulatory pressures for energy efficiency and the shift towards environmentally friendly practices across industries, reinforcing their significance in modern energy-efficient systems.

Despite their advantages, EC axial fans have prompted discussions regarding their initial investment costs, which can be higher than those of conventional fans. However, the potential for substantial energy savings and reduced maintenance needs often offsets these upfront expenses over time. As the market for EC axial fans expands, innovations in smart technology integration continue to enhance their appeal, paving the way for further advancements in performance and efficiency within various sectors.

Table of Contents

Types of EC Fans

Electronically commutated (EC) fans come in various configurations tailored to different applications and performance requirements. Understanding the distinct types of EC fans can aid in selecting the right fan for specific needs.

Axial EC Fans

EC axial fans are designed to move air parallel to the fan’s axis. These fans are particularly effective in applications requiring high airflow rates with lower pressure drops. Commonly found in HVAC systems and data centers, EC axial fans provide efficient cooling and ventilation solutions. They utilize brushless DC motors, which enhance energy efficiency and minimize operational costs. Models such as those in the Orion Fans EC Fan Series include sizes ranging from 60mm to 250mm, with some options featuring dual speed functionality.

Centrifugal EC Fans

Centrifugal EC fans operate differently by drawing air into the center of the fan and expelling it at a right angle through an impeller. This design allows them to generate higher static pressure compared to axial fans, making them ideal for applications with more resistance to airflow. Centrifugal EC fans can replace traditional AC fans in various systems due to their higher efficiency and capability to maintain performance under demanding conditions.

Integrated EC Fans

Integrated EC fans are typically incorporated directly into cooling units, replacing traditional fan and motor assemblies. This direct drive configuration results in superior energy efficiency, as the fans work more effectively within the designed system. They are often used in refrigeration units and other cooling applications, where their compact design allows for seamless retrofit installations without the need for complete equipment replacement.

Specialty EC Fans

Some EC fans are designed for specialized applications, such as environments requiring explosion-proof ratings or enhanced protection against water intrusion. For instance, models with IP68-ATEX ratings are suitable for use in explosive atmospheres or areas with flammable gases, ensuring safety without compromising performance.

Advantages of EC Fans

EC fans, or electronically commutated fans, offer numerous advantages over traditional AC fans, making them increasingly favored in various applications. Their primary benefits include exceptional energy efficiency, extended lifespan, lower maintenance costs, and adaptability to modern control systems.

Energy Efficiency

One of the most significant advantages of EC fans is their energy efficiency. Operating at efficiencies of up to 90%, EC fans consume approximately 70% less power than conventional AC fans, which typically range between 60-75% efficiency. This high level of efficiency leads to reduced energy consumption and operational costs, making them an attractive option for energy-conscious businesses and homeowners. Moreover, the ability to adjust the speed of EC fans based on real-time demand further enhances energy savings, as running an EC fan at reduced speeds can save significant energy compared to fixed-speed operation.

Longevity and Reliability

The longevity of EC fans is another critical advantage. With lifespans ranging from 30,000 to 70,000 hours, EC fans significantly outlast traditional AC models, which typically last around 10,000 hours. The lack of mechanical brushes in EC motors minimizes wear and tear, contributing to their durability and reducing the need for frequent replacements. This reliability is essential for industries that require consistent performance without unexpected downtime.

Lower Maintenance Costs

EC fans require less maintenance compared to traditional AC motors due to their simpler design with fewer moving parts. This results in lower maintenance expenses over time, as they do not require the regular replacement of carbon brushes or other components susceptible to wear. Businesses benefit from reduced maintenance downtime and costs, enhancing overall operational efficiency.

Adaptability and Control

Another advantage of EC fans is their compatibility with modern control systems. They can be integrated with building management systems through various control methods, including analog signals or digital communication protocols like Modbus RTU. This adaptability allows for precise control of fan speed, which optimizes airflow and energy consumption, particularly in applications such as HVAC systems and data centers where precise climate control is crucial.

Environmental Impact

Adopting EC fan technology aligns with broader environmental goals. By reducing energy consumption and heat waste, EC fans contribute to lower greenhouse gas emissions and support sustainability initiatives in various sectors. As industries increasingly prioritize energy conservation and environmental responsibility, the demand for EC fans continues to grow, reinforcing their position as a vital component in modern energy-efficient systems.

Applications of EC Fans

Electronically Commutated (EC) fans are versatile components widely used across various industries due to their exceptional energy efficiency and adaptability. Their applications span multiple sectors, including HVAC, data centers, refrigeration, and automotive industries.

HVAC Systems

EC fans play a critical role in heating, ventilation, and air conditioning (HVAC) systems. They significantly reduce energy consumption, providing up to 50% savings compared to traditional alternating current (AC) fans. Their compact design, cooler performance, precise speed control, and ease of installation make them ideal for modern HVAC applications, which often require continuous operation to maintain comfort levels in buildings like hotels and offices. As the HVAC industry increasingly adopts energy-efficient solutions, EC fans are becoming integral to both residential and commercial systems.

Data Centers

In data center environments, the integration of EC fans is part of a broader trend toward intelligent, adaptive infrastructure. These fans can dynamically adjust their output based on real-time system demands, improving airflow management and reducing energy waste. Their ability to operate with lower energy loss results in less heat generation, contributing to quieter operation—an essential factor in noise-sensitive environments such as data centers. Many facilities are retrofitting existing systems with EC fans to capitalize on energy savings and extend the lifespan of their infrastructure.

Refrigeration

The refrigeration industry also benefits from the application of EC fans, particularly in refrigeration condensers and commercial refrigeration units. By enhancing energy efficiency, these fans help to lower operational costs and improve the reliability of cooling systems. With improvements in features like compressor seals and insulation, the incorporation of EC fans has led to substantial reductions in energy consumption, making them a preferred choice for energy-conscious operators.

Automotive Applications

In the automotive sector, EC fans are increasingly being adopted for vehicle cooling systems to meet fuel efficiency and emissions standards. Their design facilitates easy integration into existing systems, allowing for retrofits without extensive modifications, thus providing a cost-effective solution for manufacturers. The demand for energy-efficient technologies in automotive design is rising, driven by consumer preferences for vehicles with lower operational costs and environmental impact.

Other Industries

Beyond HVAC, data centers, refrigeration, and automotive applications, EC fans find utility in diverse fields, including marine, food processing, and telecommunications. Their flexibility, efficiency, and compatibility with various systems make them a valuable asset in numerous applications where energy savings and performance reliability are crucial.

Technical Specifications

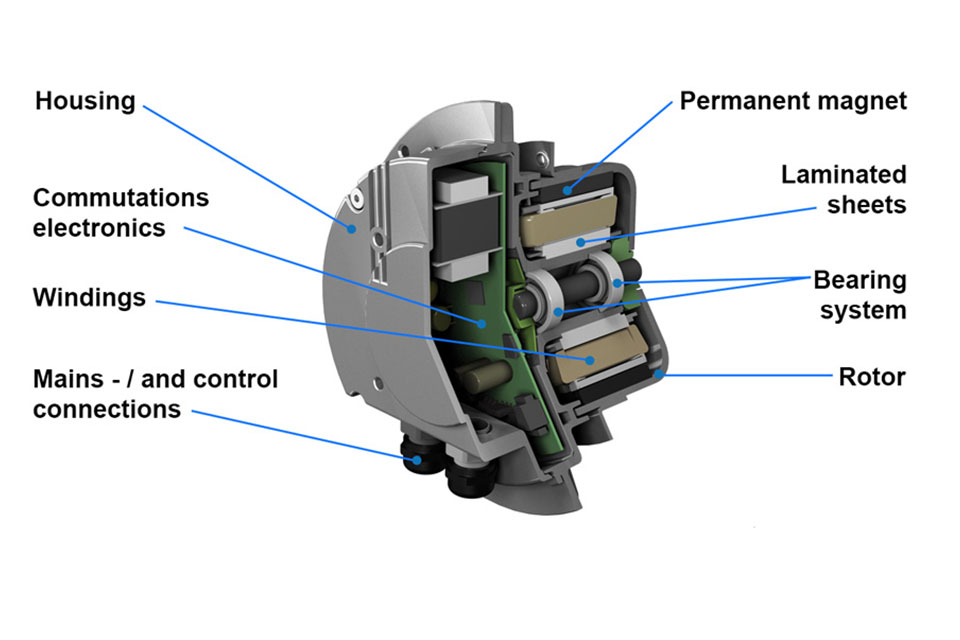

Overview of EC Technology

Electronically Commutated (EC) fans utilize brushless DC motors that incorporate advanced on-board electronics, allowing for precise control and efficiency. These motors operate with an efficiency rating exceeding 90%, resulting in energy savings of up to 50% compared to traditional motor technologies. The integration of smart control systems enables the monitoring and adjustment of parameters such as voltage, temperature, pressure, and airflow, which are essential for optimal performance.

Energy Efficiency

Rosenberg’s EC motors not only comply with the European Union’s Energy-related Products Directive (ErP) but also exceed the efficiency standards outlined in EC 60034-30, achieving ratings greater than IE4. Continuous research and development efforts focus on enhancing the energy efficiency of these products, contributing to lower operational costs and environmental benefits. With a global voltage range of 85 to 265 VAC at 50/60 Hz, these motors are versatile for international applications.

Construction and Durability

Manufactured in Germany, Rosenberg’s EC fans are designed for long-term reliability with maintenance-free operation. The compact construction and ease of installation, often described as “Plug & Play,” facilitate quick deployment without the need for complex auxiliary equipment like transformer controllers or phase angle controllers. Additionally, the reduced heat generation contributes to extended motor life, ensuring durability even in demanding environments.

Compliance and Certification

EC fans and motors are globally certified for safety, adhering to various regulatory standards, including ATEX and EN IEC 60079-7, making them suitable for applications involving flammable refrigerants like R290. Compliance with regulations from organizations such as UL, CE, RoHS, and REACH ensures that these products meet stringent international safety and performance criteria.

Versatility in Application

The versatility of EC fans is highlighted by their ability to accommodate diverse operational needs, such as constant pressure control in ducted applications and manual variable speed control via a potentiometer. This adaptability makes them ideal for industrial, commercial, and residential environments, where they can effectively contribute to energy savings and improved air quality.

Comparison with Traditional Fans

Electronically Commutated (EC) fans are often compared to traditional Alternating Current (AC) fans due to their significant advantages in performance and efficiency. EC fans offer superior energy efficiency, consuming up to 70% less power than their AC counterparts, which can lead to operational cost savings of as much as 80% in applications like HVAC systems. This efficiency is primarily attributed to the design of EC motors, which can operate at efficiencies of up to 90%.

Energy Consumption and Cost Savings

One of the most notable differences between EC and traditional fans is their energy consumption. While AC motors typically consume more electricity, EC fans have been shown to use up to 50% less energy, which not only lowers operational costs but also reduces the environmental impact associated with energy use. This energy-saving capability makes EC fans particularly appealing for continuous operation in applications such as refrigeration and HVAC, where they can maintain airflow with minimal energy expenditure.

Maintenance and Longevity

In addition to their energy efficiency, EC fans also excel in maintenance and operational longevity. The brushless design of EC motors eliminates the wear and tear associated with the brushes used in AC fans, resulting in a longer lifespan and reduced maintenance requirements. This contributes to lower long-term costs, making EC fans a more economical choice over time, despite potentially higher initial purchase costs.

Speed Control and Performance

EC fans also provide advanced speed control capabilities, allowing them to adjust their operation to match demand effectively. This modulation of speed leads to further energy savings; for instance, operating an EC fan at 80% speed can save nearly 50% of energy compared to traditional fixed-speed fans. This flexibility not only enhances efficiency but also improves comfort and reduces noise levels, providing a better overall user experience.

Application Versatility

Both EC and centrifugal fans serve important roles in various industries, but the choice between them depends on specific application needs. EC fans are increasingly used in modern HVAC systems, while centrifugal fans are more commonly employed in industrial ventilation scenarios. When selecting a fan type, factors such as energy consumption, noise levels, and maintenance requirements should be considered to find the best fit for the intended application.

Market Trends

The market for electronically commutated (EC) fans is experiencing significant growth driven by various factors, including the rising demand for energy-efficient products across multiple industries. With an increasing focus on sustainability and energy conservation, EC fans are becoming essential components in sectors such as HVAC, data centers, and industrial applications due to their superior efficiency, low noise levels, and reduced energy consumption compared to traditional AC fans.

Drivers of Growth

One of the key drivers for the EC fans market is the stringent government regulations aimed at reducing carbon emissions and promoting green building initiatives. This regulatory environment encourages the adoption of energy-efficient technologies, including EC fans, thereby fueling market growth. The increasing integration of smart technologies in building management systems also enhances the appeal of EC fans, making them a preferred choice for modern facilities.

Market Size and Forecast

The electronically commutated fans market was valued at approximately US$ 2.8 billion in 2023 and is projected to advance at a compound annual growth rate (CAGR) of 5.1% from 2024 to 2034. This growth trajectory highlights the escalating importance of EC fans in achieving energy efficiency and sustainability goals within various industries.

Industry Adoption

EC fans are gaining traction in multiple applications, including refrigeration condensers, computer room air conditioning units, and general HVAC systems. Their low operating costs and quick payback periods further contribute to their growing popularity among businesses seeking to reduce operational expenses while enhancing system performance.

Competitive Landscape

Leading manufacturers in the EC fans market are heavily investing in research and development to introduce innovative products and expand their market presence. Notable players such as Airtècnics, Continental Fan, Delta Electronics, and Ebm-papst are actively contributing to the industry’s evolution by enhancing product offerings and focusing on energy-efficient solutions.