Summary

Centrifugal fans and axial fans are two primary types of mechanical devices designed to move air and gases, each with distinct operational principles and applications. Centrifugal fans utilize a rotating impeller to draw air into the center and expel it at a 90-degree angle, generating higher pressures, making them particularly suitable for applications that require significant airflow resistance, such as HVAC systems, industrial processes, and power generation. In contrast, axial fans push air parallel to the axis of rotation, excelling in applications demanding high air volumes at lower pressures, which is common in ventilation systems and cooling processes.

The distinction between these two fan types lies not only in their design but also in their efficiency and performance characteristics. A Centrifugal fan typically demonstrates high efficiency in overcoming resistance and can operate effectively in systems requiring variable pressure, while an axial fan is favored for their ability to move large volumes of air with lower power consumption in less demanding environments. Both fan types are constructed from a variety of materials, allowing them to meet specific operational requirements across diverse industrial sectors, but they each have unique advantages and disadvantages that can influence their selection for particular applications.

Notably, the selection between centrifugal and axial fans often involves trade-offs regarding cost, efficiency, and operational capabilities. Centrifugal fans, while generally more expensive and less capable of moving high volumes of air, offer greater durability and efficiency under higher pressure conditions. Conversely, axial fans are typically more cost-effective and easier to maintain but may produce higher noise levels and lack the pressure capabilities needed for certain industrial tasks. Understanding these differences is crucial for optimizing airflow management in various settings and achieving the desired operational outcomes.

Both fan types have seen significant advancements over the years, driven by the need for energy-efficient solutions and adaptability to modern environmental standards. As industries continue to evolve, the role of centrifugal and axial fans remains critical in addressing challenges related to ventilation, cooling, and air quality management across a wide range of applications.

Table of Contents

Design and Construction

Centrifugal fans and axial fans are designed with distinct configurations and principles of operation that significantly influence their performance and applications.

Centrifugal Fans

Design Features

Centrifugal fans are mechanical devices that utilize a rotating impeller to move air or gases. They draw air into the center and expel it outward at a 90-degree angle, which allows for higher pressure generation compared to axial fans. The design of a centrifugal fan typically includes various impeller configurations, such as forward-curved, backward-inclined, and radial blades, each tailored for specific performance needs and applications. Forward-curved blades tend to move high volumes of air but often have lower static pressure capabilities, while backward-inclined blades are more efficient in high-pressure applications. Radial blades are designed for severe conditions, emphasizing structural strength and contamination resistance.

Key Components

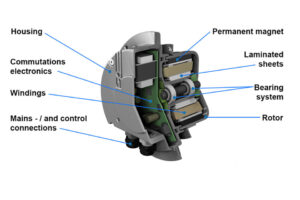

The fundamental components of a centrifugal fan include the impeller, casing, hub, shaft, and motor. The impeller, located centrally, utilizes centrifugal force to push air outward, while the casing maintains stability and controls airflow direction. The hub connects the blades to the shaft, which transmits power from the motor, usually made of high-strength materials like steel. Motors for centrifugal fans can vary, encompassing AC induction, DC, and electronically commutated motors (ECMs), allowing flexibility in design and application.

Axial Fans

Design Features

In contrast, axial fans operate by pushing air parallel to the axis of rotation. Their design typically incorporates blades that can be either fixed or adjustable pitch, enabling them to optimize airflow based on specific requirements. Common blade types include airfoil blades, which are specifically designed for high efficiency and low noise levels, making them suitable for HVAC and ventilation systems.

Construction Elements

The primary elements of axial fans are similar to those of centrifugal fans, comprising the impeller, casing, hub, and motor. However, axial fans generally feature a more streamlined design, allowing for easier integration into existing systems and improved airflow management. The casing is designed to accommodate the axial flow of air, ensuring that the fan operates efficiently within its intended application.

Material Considerations

Both types of fans can utilize a range of materials in their construction, from lightweight plastics to durable metals, depending on the environmental conditions and mechanical stresses they are expected to endure. For example, fans operating in corrosive environments may require specialized coatings to enhance durability and performance.

Performance Characteristics

Centrifugal fans and axial fans exhibit distinct performance characteristics that make them suitable for different applications. Understanding these differences is crucial for selecting the appropriate fan type for specific industrial and commercial uses.

Efficiency

Centrifugal fans typically demonstrate high efficiency under design conditions, making them particularly advantageous for tasks requiring consistent airflow against varying system pressures. Their efficiency generally peaks in low-resistance environments, where they utilize less power while delivering high airflow rates. In contrast, axial fans tend to outperform centrifugal fans in scenarios that require high flow rates at lower pressures, effectively moving larger volumes of air with minimal energy input.

Operating Speed

The operating speed is another key differentiator between the two types of fans. Axial fans operate at higher peripheral speeds compared to centrifugal fans, enabling them to achieve higher airflow rates at lower pressure differentials. This characteristic is beneficial in applications where rapid air movement is critical, such as in ventilation systems.

Power Consumption

Power consumption is a vital performance metric for both fan types. Centrifugal fans generally exhibit a slight increase in power consumption as the number of blades is altered, with variations of up to 3% observed when increasing from four to eight blades. Conversely, axial fans are often favored for their lower power consumption in high-volume applications, making them more cost-effective in energy usage over time.

Impact of Design and Maintenance

Design intricacies play a significant role in fan performance. The configuration of blades in centrifugal fans can directly influence their operational efficiency and reliability. Moreover, regular maintenance and performance monitoring are essential for ensuring that both centrifugal and axial fans operate optimally. Neglecting maintenance can lead to performance degradation, increased energy consumption, and higher operational costs.

System Effects

When installed in real-world applications, both fan types are subject to system effects, which can hinder performance. For instance, poorly designed ducting or installation can lead to increased noise, vibration, and potential failure of components. Understanding these system-related factors is critical for achieving optimal fan performance and longevity in any application.

Applications

Centrifugal fans and axial fans serve vital roles across various industries, each catering to specific operational needs. Their applications can be broadly categorized into several sectors, including HVAC systems, industrial processes, and specialized environments.

HVAC Systems

Centrifugal fans are integral to HVAC (Heating, Ventilation, and Air Conditioning) systems, where they facilitate air circulation, exhaust stale air, and maintain indoor air quality. Their ability to move large volumes of air against high pressures makes them well-suited for complex ductwork, allowing for efficient temperature regulation in residential, commercial, and industrial buildings. They also provide cooling for electronic equipment and are crucial in environments requiring precise climate control, such as data centers and laboratories.

Industrial Uses

In industrial settings, centrifugal fans are employed for a variety of applications, including dust collection, fume extraction, and material handling. Industries like cement manufacturing, steel mills, and woodworking utilize these fans to remove airborne particles and improve workplace air quality. Additionally, they are vital in processes requiring high pressure, such as drying and cooling systems, which benefit from the fans’ ability to generate substantial airflow and pressure.

Power Generation and Mining

Centrifugal fans play a significant role in power generation and mining. In power plants, they are used in cooling towers and forced draft applications to maintain optimal operating conditions. The mining industry relies on these fans for ventilation in underground shafts and tunnels, ensuring the safety and comfort of workers in confined spaces.

Clean Room and Specialized Applications

Centrifugal fans are also utilized in clean rooms and other specialized applications. They help maintain controlled environments essential in industries such as pharmaceuticals and electronics manufacturing. Furthermore, agricultural applications include crop drying and livestock ventilation, showcasing the versatility of centrifugal fans in enhancing productivity across diverse sectors.

Advantages and Disadvantages

Advantages of Centrifugal Fans

Centrifugal fans offer several key advantages that make them ideal for various industrial applications:

- High Efficiency: Centrifugal fans are known for their ability to convert energy efficiently, particularly when operating under design conditions. This efficiency reduces operational costs and allows for high-pressure airflow with minimal energy consumption, making them suitable for demanding applications such as HVAC systems.

- Durability: Built to withstand harsh environments, centrifugal fans boast robust construction that ensures long-lasting performance even in challenging conditions. Their design allows them to handle high temperatures without compromising the integrity of the motor or other components.

- Versatility: These fans can manage a wide range of airflows and pressures, making them adaptable for diverse industrial and commercial applications. They are particularly effective in environments that require high-pressure outputs or can involve corrosive atmospheres.

- Low Maintenance: With fewer moving parts compared to other fan types, centrifugal fans typically experience less wear and tear, leading to lower maintenance requirements. Regular tasks like cleaning and lubrication are sufficient to maintain their reliability.

- Noise Reduction: Certain designs, such as forward-curved centrifugal fans, operate at lower speeds, producing less noise. This feature is especially beneficial in commercial settings where a quiet atmosphere is essential.

Disadvantages of Centrifugal Fans

Despite their advantages, centrifugal fans have some limitations:

- Higher Initial Costs: The complexity of their design and construction often results in higher initial purchase costs compared to axial fans, which might deter budget-sensitive projects.

- Limited Airflow Capacity: While effective at high pressures, centrifugal fans typically do not move as much air volume as axial fans, making them less suitable for applications focused primarily on airflow rather than pressure.

Advantages of Axial Fans

Axial fans, while less powerful in terms of pressure generation, present their own set of advantages:

- High Airflow: Axial fans excel in moving large volumes of low-pressure air, making them particularly efficient for ventilation and cooling applications. They achieve great efficiency relative to their power demands, size, and weight.

- Compact Design: The compact structure of axial fans allows for easy installation and maintenance in spaces where room is limited. This characteristic is beneficial for applications where size constraints are a consideration.

- Cost-Effectiveness: Due to their high efficiency and simplicity, axial fans tend to be more cost-effective in terms of both initial investment and operational costs for applications requiring significant air movement at lower pressures.

Disadvantages of Axial Fans

Axial fans also come with disadvantages that can impact their suitability in certain contexts:

- Lower Pressure Capability: Axial fans operate at lower pressures and may not be suitable for applications that require significant pressure differentials. This limitation can hinder their effectiveness in certain industrial setups.

- Potential for Noise: In high-speed operations, axial fans can generate significant noise levels, which may be undesirable in certain environments such as offices or residential areas.

Historical Development

The evolution of fans, particularly centrifugal and axial fans, has played a crucial role in the advancement of airflow management technologies across various industries. The centrifugal fan, an early invention, dates back to 1556 when it was first utilized to ventilate mines. Despite its initial disappearance from historical records, the design experienced a resurgence in the early 1800s, marking the beginning of its prominent role in industrial applications.

Centrifugal fans are distinguished by their method of airflow generation. They utilize blades mounted around a circular hub, where the motion of the hub pulls air in and increases its pressure as it circulates. This design creates a high-pressure stream of air, allowing for efficient ventilation and cooling in various settings. As technological advancements progressed, centrifugal fans became increasingly complex, integrating aerodynamic principles and material innovations to improve their performance and energy efficiency.

Conversely, axial fans emerged as an alternative design focused on moving air parallel to the axis of rotation. The development of axial fans has also been influenced by advancements in blade shape and material properties, which have enhanced their energy efficiency and performance capabilities. The increasing demand for effective cooling and ventilation solutions, especially in industrial settings such as factories and data centers, has led to a significant rise in the use of both centrifugal and axial fans over the years.

In recent years, the industrial fan market has witnessed a surge in innovation driven by the need for energy-saving solutions and the adaptation to modern environmental standards. Both types of fans are now crucial in addressing the growing demands for effective airflow management, demonstrating their evolution from basic ventilation tools to sophisticated components integral to numerous applications.

Maintenance and Installation

Centrifugal and axial fans are essential components in various industrial and commercial applications, and their proper maintenance and installation are crucial for optimal performance and longevity.

Installation Guidelines

The installation of fans requires meticulous planning and adherence to safety regulations to avoid errors that could lead to underperformance. It is essential to use state-of-the-art equipment during the installation process to ensure efficiency and durability.

- Consultancy and Design: This phase involves analyzing specific requirements and developing tailored solutions suited for different industrial environments.

- Professional Installation: Ensure precise and safe mounting of fan housing, paying particular attention to the impeller and drive system to maintain balance and performance.

- Commissioning and Testing: Conduct comprehensive functional tests to verify correct operation and monitor initial performance for any issues that may need resolution.

Ambient Conditions

It is vital to assess the installation environment, including temperature, humidity, dust, and the presence of corrosive agents, as these factors can significantly influence fan performance. Selecting appropriate materials and protective measures can help mitigate any adverse effects on the fan’s lifespan, especially in harsh environments.

Maintenance Practices

Regular maintenance of both centrifugal and axial fans is key to prolonging their operational life and ensuring consistent performance.

- Regular Inspection: Perform periodic visual inspections to identify signs of wear, dirt accumulation, or corrosion.

- Cleaning: Regularly clean the impeller and interior casing to prevent airflow obstructions that could reduce efficiency.

- Belt and Bearing Maintenance: For fans using belts, check and adjust the tension regularly to avoid slippage and wear. Additionally, lubricate bearings according to the manufacturer’s specifications to minimize friction.

- Troubleshooting: Address common issues such as reduced airflow and excessive noise by checking for obstructions and inspecting for loose or misaligned components.

Daily and Periodic Maintenance

Beyond daily inspections, fans typically require monthly and annual maintenance work. Monthly tasks include checking and cleaning pulleys, blades, and filters, while annual tasks should involve inspecting and repairing wiring, ductwork, and insulation as needed. Following a structured maintenance schedule can help prevent premature wear and costly repairs.

By implementing these installation and maintenance strategies, operators can enhance the durability of centrifugal and axial fans, reduce downtime, and deliver consistent performance for years to come.