Summary

PWM Control for DC Fans refers to the application of Pulse Width Modulation (PWM) technology in managing the speed and performance of Direct Current (DC) fans, which are widely used in various cooling applications. PWM operates by varying the duty cycle of a digital signal, allowing for precise control over the power supplied to the fan, which optimizes airflow and temperature regulation. This method has gained significance in contemporary electronic systems due to its ability to enhance energy efficiency, reduce noise levels, and extend the lifespan of fans by minimizing wear through dynamic speed adjustments.

Notable for its energy-saving benefits, PWM control can lead to power savings of up to 50% compared to conventional DC fans that operate at a fixed speed. Furthermore, PWM-enabled fans can significantly decrease operational noise, making them particularly suitable for environments where quiet operation is essential, such as offices and residential spaces. The technology is increasingly being adopted in sectors like HVAC systems, data centers, and consumer electronics, as the demand for efficient thermal management solutions continues to grow in the context of sustainability and performance optimization.

Despite its advantages, PWM control is not without challenges. Issues such as underpowering, sensitivity to power supply variations, and the complexity of control systems can hinder the performance of PWM fans if not properly managed. Additionally, the effectiveness of PWM is contingent upon the stability of the power supply and the appropriateness of the control strategies implemented, which can complicate design and maintenance efforts.

Overall, PWM control for DC fans represents a critical advancement in cooling technology, offering a blend of efficiency, flexibility, and performance that aligns with the evolving needs of modern electronic applications. As industries continue to prioritize energy conservation and effective cooling solutions, PWM technology is poised to play a vital role in future innovations and applications.

Table of Contents

Fundamentals of PWM Control

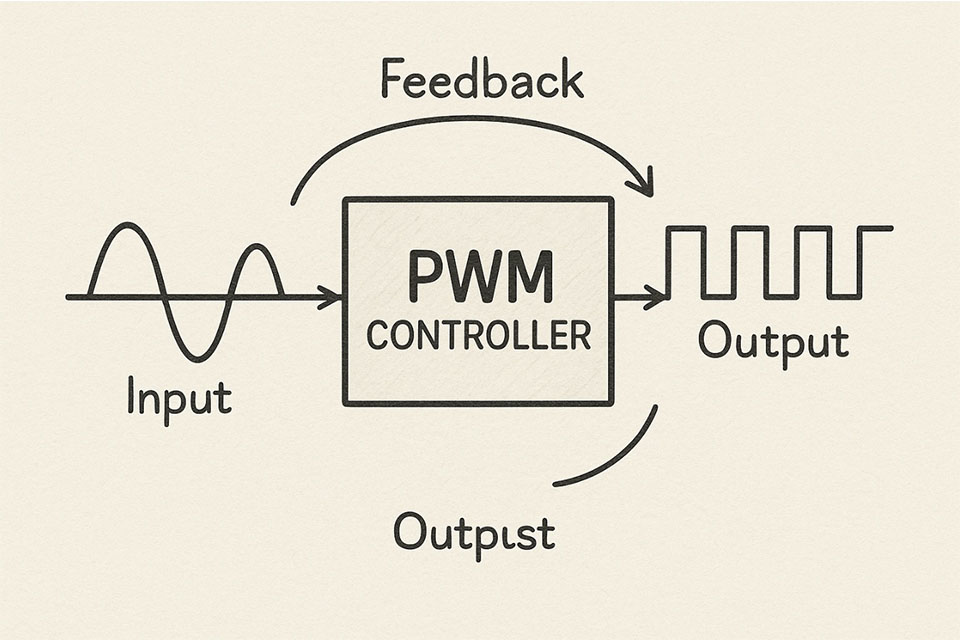

Pulse Width Modulation (PWM) is a powerful technique used to regulate power and control the operation of various electronic devices, particularly in applications involving DC fans. At its core, PWM operates by altering the duty cycle of a digital signal to modulate the average voltage and current delivered to a load. This modulation is achieved through a series of high and low signals, where the duration of the “on” time (high signal) relative to the “off” time (low signal) determines the effective power supplied to the device.

How PWM Works

The fundamental principle of PWM involves converting a continuous voltage signal into a series of discrete pulses. The energy from these pulses is then averaged out to control the power supplied to a device. By increasing or decreasing the width of the pulses, PWM can finely tune the energy delivered, allowing for precise control over the performance of devices such as DC fans.

In the context of motor control, for instance, wider pulses deliver more power, increasing motor speed, while narrower pulses reduce power, leading to a slower speed. This characteristic is especially beneficial for applications requiring variable airflow, as it allows for enhanced temperature regulation while minimizing noise levels.

Advantages of PWM

PWM offers several significant advantages over traditional methods of power control. Firstly, it enhances energy efficiency by regulating power through pulse duration instead of dissipating excess energy as heat, making it ideal for battery-powered systems. Secondly, PWM allows for precise control, enabling fine adjustments in speed, brightness, or output without the need for complex circuitry.

Additionally, PWM is versatile and adaptable, easily accommodating changing power requirements across various applications, such as motor speed control, LED dimming, and audio amplification. The simplicity and cost-effectiveness of PWM implementation, often using standard electronic components, further solidify its appeal for manufacturers seeking to optimize energy efficiency while keeping costs down.

Applications of PWM

PWM finds extensive use in a variety of applications, particularly in the control of DC motors and fans. In cooling systems, PWM allows devices to operate at lower speeds during lighter loads, which not only leads to reduced operational costs but also contributes to quieter operation. This makes PWM an essential technique in the design of energy-efficient and effective cooling solutions in both consumer and industrial settings.

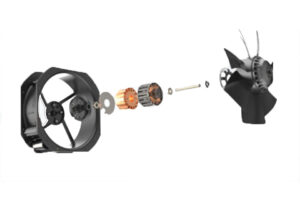

DC Fans

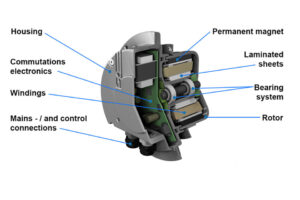

DC fans, or Direct Current fans, are commonly used cooling devices known for their efficiency and versatility. They operate based on a simple principle: the speed of the fan is determined by the voltage supplied to it, allowing users to adjust airflow by varying the voltage. Typically, DC fans are equipped with a three-pin connector, consisting of power, ground, and tachometer pins, which provide feedback on the fan’s rotational speed for monitoring purposes.

Advantages of DC Fans

DC fans offer several advantages over their AC counterparts. They are widely regarded as more energy-efficient, consuming significantly less power, which makes them a preferred choice for environmentally conscious consumers. Furthermore, they operate more quietly due to their brushless motor design, making them suitable for noise-sensitive environments such as libraries and hospitals.

DC fans also provide greater flexibility in speed control, with many models offering multiple speed settings that allow for precise adjustments to cooling performance. This capability is particularly beneficial in applications where varying temperature control is necessary.

Technical Specifications

In contrast to PWM (Pulse Width Modulation) fans, DC fans typically feature a three-pin design, which lacks the additional pin that allows for more sophisticated speed control. While PWM fans can adjust their speeds more finely through duty cycles, DC fans remain simpler and more cost-effective, making them an attractive option for users with budget constraints. Additionally, their straightforward design contributes to enhanced durability, as they are less susceptible to mechanical failures compared to more complex fan types.

Applications of DC Fans

DC fans are commonly utilized in systems that require cooling and monitoring functions, such as computers and HVAC systems. They are particularly effective in low-power applications, where their efficiency can lead to reduced operational costs over time. Furthermore, advancements in DC fan technology, including the integration of IoT capabilities for real-time monitoring, continue to expand their application potential in various fields.

PWM Control Mechanism

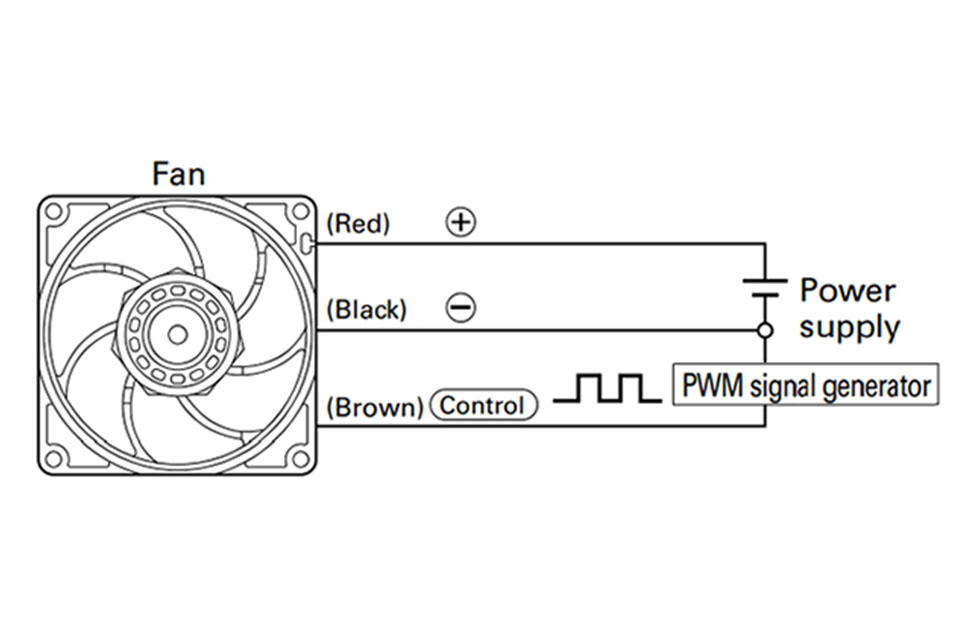

Pulse Width Modulation (PWM) control is a sophisticated technique used to regulate the speed and performance of DC fans. By adjusting the width of the pulses in the power supply, PWM enables precise control over fan speed, which is crucial for optimizing airflow and temperature management in various applications.

Working Principle of PWM

PWM operates by toggling the power supplied to the fan between on and off states at a high frequency. The average power delivered to the fan is controlled by varying the duty cycle, which is the percentage of time the signal is in the “on” state during each cycle. A higher duty cycle translates to a longer “on” duration, resulting in increased fan speed, while a lower duty cycle decreases the speed accordingly. This mechanism allows for finer adjustments in fan performance, enabling the fan to adapt to the specific cooling needs of the device it serves.

Advantages of PWM in Fan Control

Energy Efficiency

One of the key benefits of using PWM for fan control is its energy efficiency. By regulating power through duty cycle adjustments rather than dissipating excess energy as heat, PWM minimizes energy waste. This is particularly advantageous in battery-powered devices or systems with strict energy consumption requirements.

Noise Reduction

PWM control also significantly reduces operational noise levels. By allowing fans to run at lower speeds when full capacity is unnecessary, PWM minimizes the acoustic footprint of cooling systems. This is especially beneficial in environments where noise reduction is a priority, such as in residential areas or during nighttime operation.

Enhanced Performance

With PWM control, fans can dynamically respond to real-time cooling demands. This adaptability ensures optimal performance, maintaining stable temperatures in sensitive electronic devices while prolonging their lifespan through efficient operation. Additionally, because PWM signals are digitally input, multiple fans can be controlled simultaneously with precision, enhancing system versatility and flexibility.

Technical Considerations

Implementing PWM for fan control involves designing appropriate circuits to manage the PWM input signals effectively. Typically, the PWM frequency for fans is set to ensure smooth operation and avoid audible noise, with common frequencies ranging from 1 kHz to 25 kHz, depending on the specific application. The flexibility in setting both frequency and duty cycle allows engineers to tailor fan responses to varying load conditions, ensuring reliable performance under diverse operational scenarios.

Applications of PWM Control in DC Fans

PWM (Pulse Width Modulation) control technology has revolutionized the management of fan speeds in various applications, providing precise control and enhanced efficiency. The following are notable applications of PWM control in DC fans.

HVAC Systems

PWM control is also gaining traction in HVAC (Heating, Ventilation, and Air Conditioning) systems, where accurate temperature regulation is essential for energy efficiency and occupant comfort. By allowing real-time adjustments based on environmental conditions, PWM fans enhance the performance of HVAC setups. The integration of advanced temperature measurement and fan-speed control techniques is being developed to further optimize these systems, ensuring that they can meet strict power regulations and operate effectively under varying load conditions.

Computers and Servers

In desktop computers, laptops, and servers, PWM fans are primarily utilized for cooling critical components such as CPUs and GPUs. The ability to dynamically adjust fan speeds based on the thermal demands of the system allows for optimal cooling performance while minimizing noise levels. Modern motherboards often include PWM chassis fan control headers, facilitating the integration of this technology with minimal effort. During resource-intensive tasks such as gaming, video rendering, or 3D modeling, PWM fans operate efficiently to maintain system temperatures, preventing thermal throttling and ensuring optimal operational efficiency.

Data Centers

Data centers and computer rooms require robust heat management systems due to the significant amounts of equipment generating heat. In these environments, PWM fans are preferred for their efficient power usage and precise speed control capabilities. The ability to regulate fan speeds according to actual cooling needs leads to improved energy efficiency, which is critical in large-scale operations where power consumption is a major concern. Research indicates that utilizing PWM technology can reduce overall energy consumption by approximately 20% in data centers, resulting in substantial cost savings and a lower environmental impact.

Advantages of PWM Control for DC Fans

PWM (Pulse Width Modulation) control offers numerous advantages over traditional DC fan technology, enhancing performance, efficiency, and user experience.

Energy Efficiency

One of the most significant benefits of PWM-controlled fans is their energy efficiency. PWM fans dynamically adjust their speed based on the cooling requirements of the system, resulting in lower power consumption compared to fixed-speed DC fans. Studies indicate that PWM technology can lead to energy savings of up to 50% when compared to conventional DC fans that operate at a constant rate. This adaptability allows PWM fans to operate at speeds as low as 10% of their maximum performance, thereby reducing energy bills and promoting environmental sustainability.

Prolonged Fan Lifespan

PWM control can significantly extend the lifespan of fans. By modulating the fan speed according to thermal demands, unnecessary wear and tear are minimized, allowing the fan to run quieter and last longer. In contrast, traditional DC fans often run at full speed regardless of the cooling needs, leading to increased wear and potential early failure. Consequently, PWM fans not only provide better longevity but also contribute to lower maintenance costs over time.

Enhanced User Experience

Another critical advantage of PWM fans is their capability to operate quietly. By running at lower speeds when full cooling power is unnecessary, PWM fans can significantly reduce noise levels—an essential feature in noise-sensitive environments such as offices, studios, or residential spaces. Reports indicate that PWM fans can decrease noise levels by up to 30% compared to their DC counterparts, making them particularly suitable for high-performance and acoustically demanding applications.

Improved System Stability

PWM fan control contributes to enhanced system stability through efficient temperature management. By responding dynamically to thermal changes, PWM fans help maintain optimal operating conditions, thereby reducing the risk of overheating and system failures. This capability is especially vital for sensitive electronic devices, where overheating can lead to performance degradation or equipment damage. Effective thermal management with PWM technology can thus improve the reliability and performance of electronic systems over time.

Challenges and Limitations

Despite the advantages of Pulse Width Modulation (PWM) control in DC fans, several challenges and limitations can impact their efficiency and effectiveness in various applications.

Underpowering Issues

One significant challenge arises from underpowering DC blowers, which can lead to insufficient airflow, increased noise levels, and potential motor damage. When a fan does not receive the required voltage or current, it may fail to start or operate inefficiently, resulting in overheating within the systems it is meant to cool. This inefficiency is particularly concerning, as studies indicate that PWM devices can reduce their speed by as much as 40% of their rated capacity, which can exacerbate cooling problems if not adequately powered.

Sensitivity to Power Supply

The performance of PWM-controlled fans heavily depends on the stability and adequacy of the power supply. If the energy supply is inadequate, the benefits of PWM technology are rendered ineffective, leading to increased failure rates of the fan motor. Real-world examples underscore the ramifications of underperformance, with documented instances of motor damage due to insufficient energy supply emphasizing the importance of adhering to manufacturer specifications.

Complexity of Control Systems

Implementing advanced control strategies, such as dual-loop control systems that integrate inner current and outer voltage loops, can introduce complexity into the design and operation of PWM systems. While these strategies enhance performance metrics such as stability and reliability, they also require more sophisticated tuning and maintenance. Engineers must ensure that the system’s parameters are optimized, which may demand a deeper understanding of both the control algorithms and the electrical components involved.

Limitations of Performance Metrics

Evaluating the performance of PWM-controlled fans is also complicated by the need for comprehensive metrics. While key dimensions such as power factor, harmonic pollution, and efficiency are essential for assessing operational effectiveness, extreme variations in grid conditions or load demands could adversely affect system performance. Future work is required to enhance the adaptive capabilities of these systems to accommodate a broader range of operating conditions, ensuring robust performance under variable circumstances.

Future Trends

The future of Pulse Width Modulation (PWM) technology, particularly in the context of DC fans and thermal management, is poised for significant advancements driven by the increasing demand for energy-efficient solutions across various sectors. As industries prioritize sustainability and performance, PWM technology is expected to play a pivotal role in optimizing cooling systems while minimizing environmental impact.

Market Growth and Adoption

The market for PWM controllers is anticipated to experience substantial growth by 2025, reflecting a broader trend towards enhancing power management in electronic devices. This growth is fueled by the need for more efficient thermal management solutions in settings ranging from data centers to consumer electronics. As PWM technology continues to evolve, it will likely lead to the development of more sophisticated controllers that offer enhanced capabilities and improved integration with smart systems.

Enhancements in Efficiency and Performance

Advancements in PWM technology are expected to deliver remarkable improvements in operational efficiency and noise reduction. For instance, systems employing PWM can achieve up to a 30% reduction in sound output compared to traditional cooling systems, making them particularly suitable for noise-sensitive environments. Additionally, the application of PWM in regulating electric motors can provide fine control over motor speed, thereby minimizing energy loss and excessive heat generation. Such efficiency improvements are crucial in high-performance settings, where effective temperature management is essential.

Integration with Smart Technologies

Future trends indicate a growing integration of PWM systems with smart technologies, such as Internet of Things (IoT) devices. This integration could facilitate real-time monitoring and adaptive control of cooling systems, leading to optimal performance based on dynamic thermal demands. As the need for energy-efficient and sustainable solutions becomes increasingly urgent, the potential for PWM technology to contribute to smart building and smart grid applications will likely be a focal point for ongoing research and development.