Summary

AC axial fans are specialized ventilation devices designed to efficiently move large volumes of air, making them integral to various applications, from residential cooling to industrial ventilation. Characterized by their axial airflow pattern, these fans leverage specific design features—including optimized blade configurations and efficient motors—to create effective airflow while minimizing energy consumption. Their ability to deliver high airflow rates, coupled with their versatility, has established AC axial fans as a reliable workhorse in HVAC systems, contributing significantly to indoor air quality and climate control across numerous sectors, including residential, commercial, and industrial environments.

The notable efficiency and cost-effectiveness of AC axial fans, along with advancements such as the integration of Electronically Commutated (EC) motors, have enhanced their appeal in the market. These fans can operate effectively in diverse settings, from homes to data centers, where managing heat and humidity is critical. Despite their advantages, AC axial fans are not without limitations, including lower static pressure capabilities compared to centrifugal fans and potential noise concerns, which can affect their suitability for certain applications. These factors necessitate careful selection and installation to optimize performance.

In addition to their technical merits, AC axial fans play a pivotal role in addressing modern challenges related to urbanization and environmental sustainability. As cities grow and air quality becomes a pressing concern, these fans help facilitate improved air circulation, thus contributing to healthier living and working environments. The ongoing shift toward energy-efficient solutions further emphasizes their importance, as industries and homeowners seek to reduce operational costs and environmental impacts.

The future of AC axial fans appears promising, driven by technological innovations and a growing focus on sustainability. Trends such as the integration of IoT technologies and advanced data analytics are expected to enhance fan performance and operational efficiency, ensuring their continued relevance in an evolving market. As advancements in design and engineering continue, AC axial fans will remain a vital component in the quest for effective ventilation solutions, shaping the landscape of air management in the years to come.

Table of Contents

Design and Operation

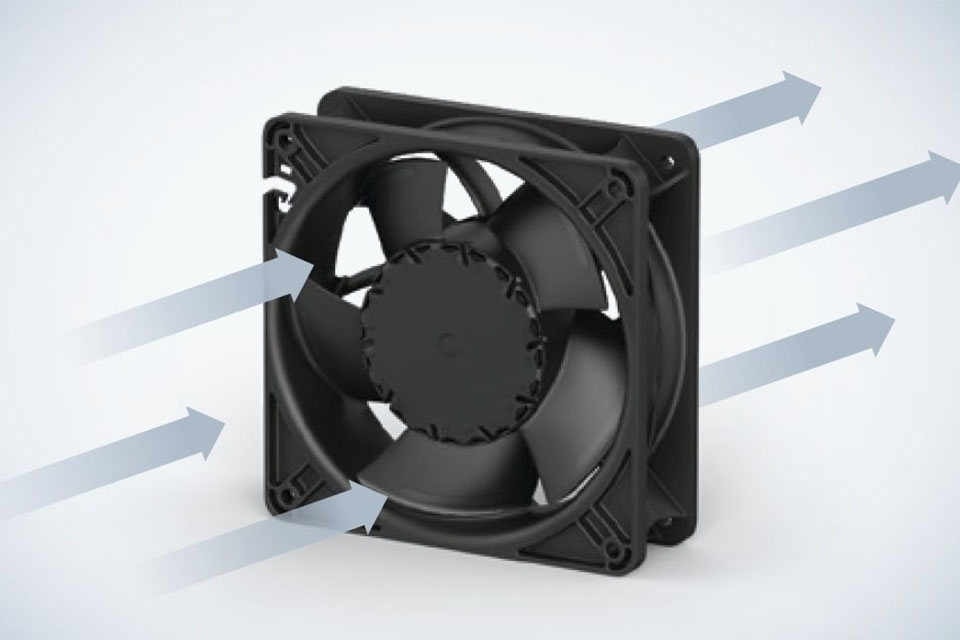

AC axial fans are engineered with specific design elements to optimize their performance in various applications, particularly in general ventilation and cooling systems. The fundamental design features include the configuration of the fan blades, the efficiency of the motor, and the selection of appropriate materials. These components work in concert to create effective airflow while maintaining energy efficiency.

Blade Design

The blade design of an AC axial fan is critical for its operational effectiveness. The blades are typically mounted on a hub and are shaped to create a pressure difference between the front and back sides, facilitating airflow. The geometric form and angle of the blades significantly influence the fan’s performance; as the flow rate increases from zero, the efficiency initially rises to a maximum point before declining.

Motor Efficiency

The motor used in AC axial fans is another crucial aspect of their design. AC motors tend to have higher energy consumption, especially when operating at full capacity. However, advancements in motor technology, including the adoption of Electronically Commutated (EC) motors, offer a promising solution. EC motors combine the benefits of AC and DC motors, providing improved energy efficiency and better speed control, making them increasingly popular in modern cooling fan systems.

Fan Frame and Accessories

The fan frame, also known as the shroud or housing, plays an essential role in supporting the motor and impeller while directing airflow efficiently. Its configuration can significantly affect both performance parameters and noise levels of the fan. Proper installation of the fan, including strategic mounting near windows or openings to promote air exchange, is vital for optimal performance.

Operational Considerations

When designing and operating AC axial fans, engineers must take into account several operational factors. These include the size of the space to be cooled, the operating environment, and noise levels, which must remain below 85 dB to prevent hearing loss in workplace settings. Tailoring fan specifications to meet these requirements ensures that they deliver the necessary airflow and cooling performance for diverse industrial and commercial applications.

Applications

AC axial fans are widely utilized across various industries and sectors due to their versatility and efficiency in air movement and ventilation. Their applications range from residential cooling systems to large-scale industrial environments, making them integral components in ensuring optimal airflow and climate control.

Residential Use

In residential settings, AC axial fans are commonly employed in air conditioning and ventilation systems. They facilitate proper airflow, enhancing indoor air quality by reducing humidity levels and circulating clean air throughout living spaces. Additionally, they play a crucial role in exhaust ventilation, helping to eliminate stale air and odors from kitchens and bathrooms.

Commercial and Industrial Applications

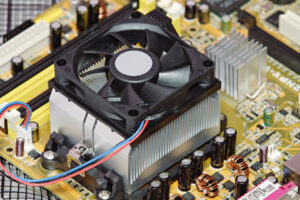

AC axial fans are essential in commercial buildings, including offices, malls, and data centers, where they support HVAC systems by maintaining comfortable indoor climates and ensuring efficient energy use. In industrial contexts, they are utilized for cooling purposes in manufacturing processes, preventing overheating of equipment and maintaining operational efficiency. Their robust design makes them suitable for heavy-duty applications, such as in power distribution systems and telecommunications, where temperature regulation is critical to prevent heat-related failures.

Specialized Environments

Axial fans also find applications in specialized environments such as data centers, cleanrooms, and cold storage facilities. In data centers, they manage the heat generated by servers, ensuring optimal performance and preventing equipment failures due to overheating. In cleanrooms, they help maintain contamination-free environments by ensuring proper airflow and filtration, which is crucial in industries such as pharmaceuticals and semiconductor manufacturing.

Renewable Energy Systems

Another notable application of AC axial fans is in renewable energy systems, such as wind and solar energy installations, where they contribute to cooling and ventilation of various components, enhancing overall system efficiency and reliability.

Advantages

AC axial fans offer several key benefits that make them a preferred choice for various ventilation and cooling applications.

High Airflow Efficiency

One of the most notable advantages of AC axial fans is their ability to move large volumes of air efficiently, which is crucial for applications that require constant ventilation and cooling. They are designed to provide high airflow rates while maintaining relatively low operational costs, making them an economical choice for both industrial and residential settings. These fans typically achieve airflow rates ranging from 2,000 to 30,000 m³/h, with some high-capacity models capable of exceeding 50,000 CFM, which is essential for large environments such as power plants and manufacturing facilities.

Energy Efficiency

AC axial fans are also recognized for their energy efficiency. Their simple design minimizes friction losses and power consumption, allowing for lower operational costs while still delivering optimal performance. Upgrading to energy-efficient axial fans in HVAC systems can lead to significant energy savings and reduced environmental impact, benefiting both the user and the environment.

Cost-Effectiveness

In addition to energy savings, AC axial fans are generally more affordable to operate due to their minimal maintenance requirements and longer service life. For example, they can last between 10 to 15 years before needing replacement, which is advantageous for budget-conscious applications. Regular maintenance practices further enhance their durability and efficiency, preventing costly downtimes and extending the lifespan of the equipment.

Versatility and Compact Design

These fans are highly versatile and can be installed in various settings, from industrial ventilation systems to small appliances like vending machines and air compressors. Their compact and streamlined design allows them to be installed in areas with limited space, making them suitable for a wide range of applications without compromising performance. Furthermore, the flexibility of axial fans enables retrofitting and upgrades to existing systems, enhancing operational efficiency at a relatively low cost.

Disadvantages

AC axial fans, while widely used for general ventilation, come with several notable disadvantages that may affect their suitability for specific applications.

Low Pressure

One of the primary drawbacks of AC axial fans is their low static pressure capability. Unlike centrifugal fans, which are designed to generate higher pressure, axial fans may struggle to maintain effective airflow in systems that require significant resistance, such as long duct runs or complex ventilation networks. This limitation makes them less suitable for applications that demand high-pressure air delivery.

Noise Levels

Noise generation is another concern associated with AC axial fans. Depending on the fan’s design and the specifics of its application, axial fans can produce higher audible noise levels compared to centrifugal fans. This characteristic can be particularly problematic in environments where noise reduction is essential, such as offices or residential areas. The noise level often increases with the amount of air moved, which can be a critical consideration when designing ventilation systems.

Maintenance and Installation Challenges

AC axial fans require careful installation and ongoing maintenance to ensure optimal performance. Improper installation can lead to inefficient airflow and increased noise, while regular monitoring is necessary to address issues such as bearing wear and vibration. In sensitive environments, the acoustic impact of these fans may necessitate additional sound insulation or isolation measures, complicating their integration into existing systems.

Performance in Harsh Environments

While AC axial fans can perform adequately in many scenarios, their durability may be compromised in harsh or dirty environments containing particulates, hot air, or corrosive gases. In such conditions, centrifugal fans often offer greater reliability due to their robust design and ability to handle higher pressures and more challenging operating conditions.

Selection Criteria

When selecting AC axial fans for general ventilation applications, several key criteria should be considered to ensure optimal performance, efficiency, and suitability for specific environments.

Evaluation Criteria

Cost and Performance

Initial cost, performance, and reliability are primary evaluation criteria for fan selection. The balance among these factors may vary based on the specific requirements of the installation, such as the size of the space and the expected airflow needs.

Airflow Capacity

The airflow capacity is another critical aspect, with the medium flow capacity segment (5,000 – 50,000 CFM) leading the market due to its versatility and balance between airflow volume and energy efficiency. For applications requiring larger volumes of air movement, such as in power plants or large manufacturing halls, high flow capacity fans (above 50,000 CFM) are becoming increasingly essential, projected to grow at a CAGR of 5.4% from 2025 to 2030.

Noise Levels

Engineers must prioritize noise reduction strategies to minimize the acoustic impact of fan installations, especially in sensitive environments. Techniques such as sound insulation, strategic fan placement, and the selection of certified fans (compliant with safety and environmental standards like RoHS and EMC) are effective methods for achieving quieter operations. It is crucial that noise levels in workplace settings are maintained below 85 dB to prevent hearing loss, influencing fan selection based on noise performance and application.

Efficiency Ratings

Efficiency ratings are also vital in the selection process. Understanding performance characteristics, such as the relationship between flow rate and efficiency, helps in identifying the most suitable fan type for a given application. Airfoil impellers, designed to maximize efficiency similar to airplane wings, are particularly recommended for high-performance setups.

Installation Considerations

Proper installation is essential to achieve optimal fan performance. Key considerations include ensuring adequate clearance for operation, airflow direction, and mounting options. The influence of installation conditions on airflow and noise levels must not be overlooked, as factors like elbows and transitions can disrupt airflow and affect the overall efficiency of the system.

By considering these selection criteria, engineers and designers can ensure that they choose the most effective AC axial fan for their ventilation needs, balancing performance, cost, and noise considerations for optimal operational efficiency.

Maintenance and Troubleshooting

Regular maintenance of AC axial fans is essential for ensuring optimal performance, extending equipment lifespan, and preventing costly downtime. A comprehensive maintenance plan should include cleaning, inspection, lubrication, and replacement of worn-out parts to address common issues such as low efficiency and high energy consumption.

Key Maintenance Practices

Regular Inspections

Conduct routine inspections to identify any signs of wear and tear. These should include listening for abnormal sounds during operation, which may indicate issues such as bearing degradation, loose components, or misalignment. A thorough visual inspection of the fan and motor is also necessary to check for physical damage like cracks or corrosion.

Cleaning

Ensure that ventilation systems are cleaned regularly to prevent dust accumulation. Clean air filters are vital for maintaining airflow; dirty filters can obstruct airflow, forcing the system to work harder, which can lead to increased energy bills. Additionally, the housing and ducts should be inspected for blockages or damage that could impact airflow.

Lubrication

Proper lubrication of bearings and motors is crucial for operational efficiency. Following the manufacturer’s specifications for lubricant type and application intervals is recommended, as both over-lubrication and under-lubrication can lead to damage. Regularly lubricating these components helps reduce friction and extends service life.

Electrical and Mechanical Checks

Routine checks of electrical connections and wiring integrity are necessary to prevent electrical failures. This includes verifying voltage at motor terminals and assessing motor amperage draw using calibrated tools. Furthermore, for belt-driven fans, monthly inspections should be conducted to ensure proper belt condition and tension, as incorrect tension can lead to premature wear and inefficiency.

Troubleshooting Common Issues

Identifying Performance Problems

If the fan shows signs of poor performance, such as weak airflow or excessive noise, it is essential to perform a systematic troubleshooting process. Checking for proper power supply voltage and inspecting the fan for any physical damage can help identify the root cause of performance issues.

Monitoring Vibration and Noise

Abnormal vibrations can signal an imbalance or misalignment within the fan. Using vibration analysis tools can provide real-time monitoring, allowing for predictive maintenance rather than reactive repairs. Monitoring the fan’s noise levels can also indicate potential problems; for instance, unusual sounds during operation may require immediate investigation to avoid further damage.

Overheating Issues

Overheating is a common problem, often caused by the blower motor working overtime due to other underlying issues. If there is no airflow, it may indicate a malfunctioning blower motor or blockage in filters or ducts. It is important to address overheating promptly to prevent activation of thermal limit switches that can shut down the motor.

Comparison with Other Fan Types

Efficiency and Cost

When comparing the operational costs, AC axial fans tend to have lower initial costs and are more versatile for various applications, ranging from personal cooling to large industrial systems. However, centrifugal fans may offer better efficiency and durability over time, which can be a critical consideration for long-term applications. In terms of energy consumption, DC axial fans are more energy-efficient than their AC counterparts, especially when used in variable load scenarios.

Noise Levels

Noise generation is another significant factor in the comparison between these fan types. Axial fans are typically quieter than centrifugal fans, making them preferable in environments where noise levels need to be minimized, such as offices or residential spaces. Advanced noise reduction technologies in modern axial fans further enhance their suitability for such applications. However, both types can produce audible noise that may need to be managed through proper placement and installation techniques.

Application Suitability

Axial fans excel in applications requiring high airflow and low pressure, such as general cooling and ventilation systems. They are particularly effective in scenarios where space is limited and airflow requirements are high. On the other hand, centrifugal fans are better suited for applications that involve higher pressure and more complex duct systems, making them preferable for industrial processes and systems requiring greater resistance to airflow.

Future Trends and Innovations

The AC axial fans market is poised for significant evolution driven by advancements in technology and a heightened focus on sustainability. Innovation plays a critical role in maintaining momentum within the industry, with companies increasingly adopting AI-driven solutions and digital platforms to enhance performance and efficiency. The introduction of eco-friendly materials and automation-enhanced systems aligns with growing customer demands for sustainable and environmentally responsible products.

Technological Advancements

The design and engineering of axial fans have benefited greatly from progress in mechanical engineering, particularly in aerodynamics, fluid mechanics, and materials science. These advancements have resulted in more efficient, quieter, and durable fans. Engineers are continuously exploring new technologies and design methodologies to optimize fan performance and improve energy efficiency, which will remain a crucial focus as the industry evolves.

Market Dynamics

The future outlook for the AC axial fans market is optimistic, driven by increasing demand for effective air circulation solutions across diverse sectors. The industry’s growth is supported by an emphasis on energy efficiency and sustainability, which is expected to persist in the coming years. Additionally, strategic partnerships, mergers, and acquisitions among leading manufacturers are anticipated to strengthen market positions and expand global reach, enhancing competitive dynamics within the industry.

Integration of IoT and Data Analytics

The integration of Internet of Things (IoT) technologies and advanced data analytics into axial fan systems is revolutionizing operational efficiency. Predictive maintenance systems and real-time monitoring capabilities provide companies with a competitive edge, enabling proactive management of fan performance and energy consumption. As IoT adoption expands, it is likely to become a cornerstone of future innovations in the axial fan market.