Summary

Electronically commutated (EC) fans are advanced ventilation devices that utilize brushless DC motor technology to deliver efficient and reliable airflow across a variety of applications. Known for their energy efficiency, EC fans can achieve efficiency levels of up to 90%, significantly outperforming traditional alternating current (AC) fans. This technology is particularly notable in industries such as heating, ventilation, and air conditioning (HVAC), where energy conservation and effective air management are paramount in reducing operational costs and minimizing environmental impact.

The two primary types of EC fans are axial and centrifugal fans, each serving distinct functions based on their design. Axial fans are commonly employed for low-pressure applications that require high airflow, making them ideal for residential and commercial ventilation systems. In contrast, centrifugal fans excel in high-pressure environments, often used in HVAC systems and industrial applications that demand robust airflow management under challenging conditions. As energy efficiency regulations tighten globally, the adoption of EC fan technology has surged, making them integral to modern energy-efficient infrastructure.

Despite their advantages, the initial cost of EC fans can be a barrier to entry for some businesses, particularly small and medium enterprises, which may prioritize lower upfront expenses over long-term savings. Additionally, challenges associated with the integration of EC fans into existing systems can complicate their adoption, especially in older buildings that rely on outdated technologies. These issues underscore the ongoing debate about balancing initial investments with potential long-term benefits, as well as the broader market transition toward energy-efficient solutions.

As demand for smart and sustainable building technologies grows, the future of EC fans looks promising, with advancements in IoT integration and AI-driven performance optimization on the horizon. Their ability to adapt to varying airflow requirements positions them as essential components in achieving energy efficiency goals across various sectors, including data centers, healthcare facilities, and industrial settings, ultimately supporting a global shift towards sustainability.

Table of Contents

Types of EC Fans

EC fans, or electronically commutated fans, come in various designs tailored for different applications, each leveraging advanced technology to enhance performance and efficiency. The primary types of EC fans include axial fans and centrifugal fans, each serving distinct purposes in various industries.

Axial Fans

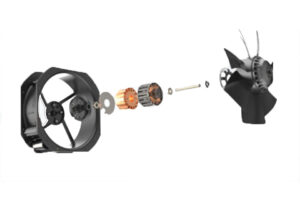

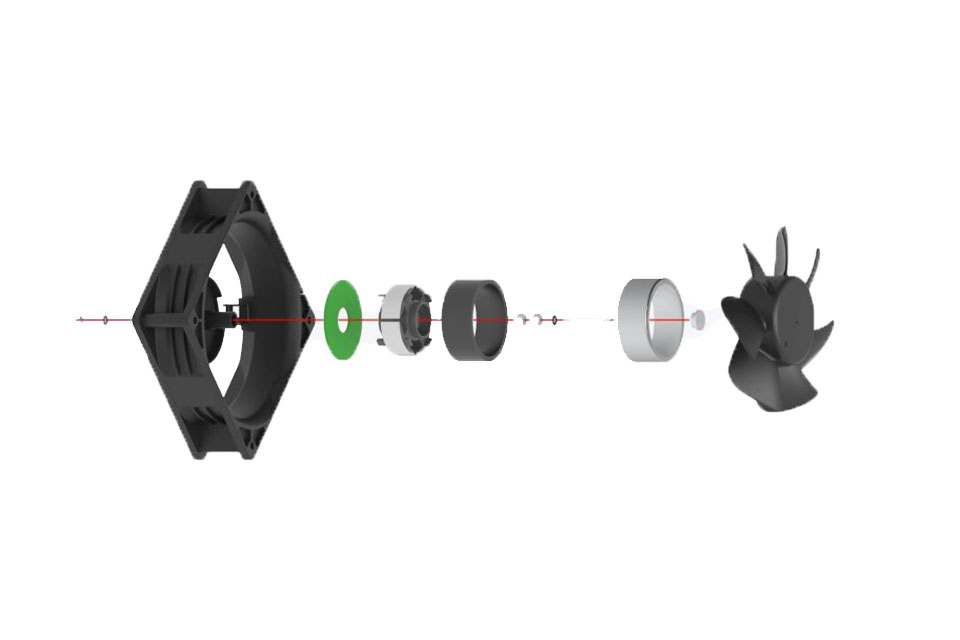

Axial fans are the most common type of EC fans, recognized for their ability to move large volumes of air at low pressure. They are widely utilized in applications such as ventilation, cooling, and air conditioning in residential, commercial, and industrial settings. One of the key advantages of axial EC fans is their high efficiency, which can reach up to 90%, making them significantly more energy-efficient than traditional AC fans. Additionally, advancements in fan blade design and motor technology have further improved their performance and appeal, particularly in environments where maintaining optimal air quality and ventilation is essential.

These fans typically feature brushless DC motors, which offer enhanced reliability and require minimal maintenance compared to conventional fan technologies. The incorporation of IoT-enabled features in some models allows for advanced system diagnostics and airflow optimization, catering to the growing demand for smart automation in buildings.

Centrifugal Fans

Centrifugal fans also represent a vital category of EC fans, particularly in applications requiring high static pressure and significant airflow. They are commonly employed in HVAC systems, air conditioning, and ventilation applications. The EC motors used in centrifugal fans contribute to improved energy efficiency and reduced operating costs compared to traditional fan designs. Their compact size and extended operational lifespan further reduce maintenance requirements, making them an attractive option for various industries.

Centrifugal fans excel in scenarios where high-pressure capabilities are needed, making them suitable for applications that necessitate efficient air circulation under challenging conditions. The ongoing transition towards energy-efficient solutions across industries ensures a growing acceptance of EC centrifugal fans in both existing and new installations.

Applications of EC Fans

EC fans, or Electronically Commutated fans, are widely utilized across various industries due to their efficiency and versatility. These fans are especially prominent in applications that require effective airflow management and energy conservation.

HVAC Systems

One of the primary applications of EC fans is in heating, ventilation, and air conditioning (HVAC) systems. They play a crucial role in maintaining indoor air quality and comfort, particularly in environments like office buildings and hotels where the HVAC systems may need to operate continuously to accommodate high occupancy levels. By using EC fans, these systems can achieve significant energy savings, consuming up to 50% less electricity compared to traditional AC motors.

Specialized Applications

In addition to standard HVAC and industrial uses, EC fans are also employed in specialized applications, such as in trench heaters and floor convectors, where compact and efficient airflow is required. Companies like Airtècnics focus on developing innovative EC fan solutions tailored to unique cooling needs, further demonstrating the adaptability of this technology.

Data Centers

The rise of data centers has created a growing demand for efficient cooling solutions, where EC fans are integral to managing heat generated by servers. The global data center cooling market, is expected to grow significantly, highlighting the increasing reliance on advanced fan technologies to maintain optimal operating temperatures while minimizing energy consumption. EC fans are particularly beneficial in environments that require precise cooling, such as cloud computing and AI infrastructure, allowing for intelligent management of airflow and cooling efficiency.

Industrial Applications

EC fans find diverse applications in various industrial sectors, including food processing, agriculture, and laboratories. Their ability to provide precise speed control and low energy consumption makes them suitable for optimizing air circulation in these settings. For example, in the food industry, maintaining specific temperature and humidity levels is critical for product preservation, where EC fans can contribute significantly to system performance.

Advantages of EC Fans

EC (Electronically Commutated) fans offer a myriad of advantages that make them increasingly popular across various applications, particularly in the industrial, commercial, and residential sectors.

Energy Efficiency

One of the most significant advantages of EC fans is their remarkable energy efficiency. They can achieve efficiency levels as high as 90%, outperforming traditional AC fans, which typically consume more energy and have lower efficiency ratings. This high efficiency translates to substantial energy savings, with estimates suggesting that EC fans can save up to 70% of the energy consumed by AC motors. The reduced energy consumption not only lowers operational costs but also contributes to a decreased environmental impact.

Variable Speed Control

EC fans are designed to operate with variable speed control, allowing for real-time adjustments based on demand. This adaptability enables substantial energy savings, particularly in applications like HVAC systems and data centers, where precise control over airflow is crucial. By modulating their speed according to specific heating or cooling requirements, EC fans ensure that energy is used efficiently, only consuming what is necessary at any given moment.

Longevity and Reliability

The longevity of EC fans is another critical advantage, with lifespans significantly longer than traditional AC models. This extended lifespan reduces maintenance requirements and costs, making EC fans a more cost-effective choice in the long run. The brushless design of EC motors contributes to their durability and reliability, minimizing mechanical wear and tear.

Noise Reduction

Noise levels are a pivotal consideration in many applications, particularly in settings that demand quiet operation, such as hospitals and libraries. EC fans inherently produce lower noise levels compared to conventional motors, thanks to their advanced design and electronic controls, which result in smoother operation with less vibration. This feature enhances the overall comfort of environments where they are installed, making EC fans an appealing option for noise-sensitive applications.

Integration with Energy Efficiency Strategies

To maximize the benefits of EC fans, they can be integrated into broader energy efficiency strategies. When paired with other energy-saving technologies, their impact on performance improvements and energy savings can be amplified. Continuous monitoring of energy usage further reveals optimization opportunities, ensuring that systems operate at peak efficiency.

Applications

Given their advantages, EC fans are becoming essential in various applications, including HVAC systems, refrigeration condensers, and computer room AC units. The growing emphasis on sustainability and energy conservation is a significant driver behind the increasing adoption of EC fan technology, as businesses and individuals alike seek more efficient solutions. As the demand for smart buildings and energy-efficient appliances rises, the relevance of EC fans in achieving these objectives continues to grow.

Comparison with Traditional Fans

EC (Electronically Commutated) fans have several notable advantages over traditional AC (Alternating Current) fans, making them increasingly popular in various applications. One of the primary distinctions is their energy efficiency; EC fans can reduce energy consumption by up to 50% compared to AC motors, resulting in lower operational costs and a smaller environmental footprint. This efficiency is attributed to their advanced motor technology, which allows for better energy utilization and reduced heat loss.

Initial Costs and Long-Term Benefits

While the initial purchase price of EC fans can be significantly higher—up to 50% more than traditional variable speed drives (VSDs)—the long-term savings in energy and maintenance often justify the investment. EC fans not only reduce energy consumption by 25-30% but also have built-in features that prevent airflow loss and lower maintenance requirements, leading to improved reliability. Moreover, their longer service life decreases the frequency of replacements, further contributing to cost savings over time.

Noise Levels

In terms of operational noise, EC fans are generally quieter than their AC counterparts. This is particularly advantageous in environments where low noise levels are essential, such as offices and residential areas. The smoother electronic commutation of EC motors contributes to this noise reduction, enhancing their appeal for sensitive applications.

Market Adoption Challenges

Despite their advantages, the higher upfront costs of EC fans can deter adoption, particularly among small and medium enterprises that may prioritize initial investment over long-term savings. Additionally, installation complexities and compatibility issues with existing systems can further limit their market penetration. Some regions also face challenges in accessing maintenance and repair services for EC components, which can affect the overall cost-benefit appeal of these advanced fans.

Potential Drawbacks and Limitations

While electronically commutated (EC) fans present numerous advantages, there are several potential drawbacks and limitations that should be considered when evaluating their use in various applications.

Maintenance Complexity

Post-maintenance procedures for EC fans may require specialized knowledge, complicating routine maintenance efforts. While these fans reduce many common failure points associated with traditional systems, the onboard electronics may still necessitate professional expertise for troubleshooting and repairs.

Efficiency Concerns

One of the significant drawbacks of EC fans is their comparatively poor efficiency, particularly in the part-load range, where they are inferior to electronically commutated alternatives. This can limit their effectiveness in applications where variable loads are common.

Higher Initial Costs

The initial investment required for EC fans is often higher than that of traditional AC or variable speed drive (VSD) fans, which can deter adoption among small and medium-sized businesses, especially in cost-sensitive industries. Although EC fans offer long-term energy savings and reduced maintenance costs, the upfront costs may pose a barrier for many potential users.

Integration Challenges

Integrating EC fans into existing infrastructure can also be complex and costly, particularly in older buildings or industrial facilities that rely on outdated systems. Retrofitting existing HVAC systems to accommodate EC technology may necessitate significant investment and expertise, which can hinder adoption in regions with limited access to advanced technologies and skilled labor.

Static Pressure Limitations

EC fans may have different static pressure capabilities compared to the conventional fans they replace. Insufficient static pressure generated by EC fans can lead to poor air distribution, decreased airflow, and compromised comfort levels within a space. Careful evaluation of static pressure requirements is essential to ensure that the selected EC fans can adequately meet the system’s demands.

Noise Sensitivity

Although EC motors are generally quieter than traditional AC induction motors, their performance can still be influenced by the specific application environment. In cases where noise sensitivity is a critical factor, careful consideration of the fan’s operational noise levels is necessary to ensure compliance with environmental and operational standards.

Future Trends in EC Fan Technology

The future of electronically commutated (EC) fan technology is poised for significant advancements, primarily driven by a growing emphasis on energy efficiency, intelligent integration, and sustainability. As various sectors prioritize resource conservation, EC fan devices are becoming essential components in these efforts. Innovations such as Internet of Things (IoT) integration and predictive maintenance are expected to enhance their functionality, allowing for real-time monitoring and performance optimization.

Market Growth and Demand

The EC fan market reflects an increasing demand for energy-efficient solutions, particularly as regulations concerning energy consumption become more stringent. This trend not only promises operational cost savings but also supports broader environmental objectives.

Technological Advancements

Key technological trends in the EC fan industry focus on improved energy efficiency and intelligent control systems. For example, the integration of AI algorithms allows for dynamic adjustments of fan speeds based on real-time data such as airflow, temperature, and humidity. This adaptive capability not only minimizes energy wastage but also extends the lifespan of the equipment, aligning with goals to reduce greenhouse gas emissions as outlined by environmental agencies.

Moreover, the development of high-performance EC centrifugal fans is expected to shape the future landscape, driven by a quest for lower carbon footprints and enhanced product durability.

Expanding Applications

EC fans are increasingly being retrofitted into existing systems across various sectors, including HVAC, data centers, and industrial applications. Their versatility makes them suitable for a wide range of uses, from enhancing air circulation in agricultural settings to improving environmental conditions in laboratories.

The demand for EC fans is further amplified by the growing trend towards smart buildings and factories, where automated and remotely controlled ventilation systems are becoming the norm.