Summary

A DC axial fan is a type of electrical fan designed to move air efficiently and quietly by rotating blades around an axis, utilizing direct current (DC) power. Distinguished by their energy efficiency and compact design, DC axial fans are increasingly utilized across diverse applications, including electronics cooling, industrial automation, and telecommunications, where effective thermal management is critical. The notable advantage of these fans is their ability to achieve up to 80% energy savings compared to traditional alternating current (AC fans), aligning with the growing demand for sustainable and eco-friendly solutions in various industries.

The construction of DC axial fans typically involves four main components: the rotor, stator, motor, and outer frame, each selected for their materials to optimize performance and durability. Technological advancements in the field have led to innovations such as brushless motor designs, which enhance efficiency and reduce maintenance needs, as well as the integration of smart technologies that enable remote monitoring and predictive maintenance. These advancements not only improve operational performance but also contribute to the increasing popularity of DC axial fans in modern engineering applications.

Despite their many benefits, DC axial fans do have limitations. They are less effective in high-static pressure environments compared to centrifugal fans, and certain models may generate noise levels that can be problematic in sensitive settings. Furthermore, as manufacturers strive for greater energy efficiency, competition in the market has intensified, leading to challenges regarding pricing and profitability. Companies must navigate these dynamics while addressing issues related to global supply chain disruptions that can affect material availability and production costs. Overall, the evolution of DC axial fans reflects ongoing trends toward efficiency and sustainability in various industries, ensuring their relevance in future cooling solutions.

Table of Contents

Design and Construction

DC axial fans are engineered with a focus on efficiency, performance, and durability. Their design integrates advanced technologies and materials that enhance their operational capabilities and longevity.

Components of DC Axial Fans

The construction of a DC axial fan primarily involves four critical components: the rotor, stator, motor, and outer frame. Each component is crafted from specific materials chosen for their unique properties that contribute to the fan’s overall efficiency and reliability.

Rotor Design

The rotor is a crucial part of the fan that directly influences airflow generation. It typically consists of an iron core and wound coils, and in brushless models, permanent magnets are incorporated to improve efficiency. The blade design of the rotor plays a significant role in determining the performance of the fan. Features such as blade shape, pitch, and curvature are optimized to enhance airflow while minimizing noise levels. Aerodynamic improvements in blade design are essential for achieving efficient airflow and reducing turbulence during operation.

Stator Configuration

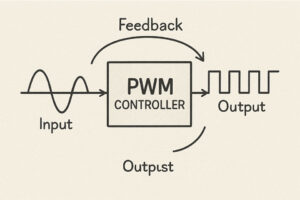

The stator is another vital component that consists of an iron core and wound coils, which create a magnetic field to interact with the rotor. In brush-type motors, brushes maintain a sliding electrical connection with the rotor, whereas brushless motors eliminate this need, thereby reducing friction and maintenance requirements. This design innovation allows for quieter operation and increased energy efficiency, making brushless DC motors increasingly popular in modern fan applications.

Materials Used

The materials utilized in the construction of DC axial fans are selected to ensure durability and performance. Common materials include aluminum for the blades, which provides a lightweight yet sturdy structure that can withstand extreme conditions. Additionally, the outer frame is often constructed from robust materials that contribute to the fan’s overall stability and resistance to environmental factors.

Technological Advancements

Recent advancements in fan design include the integration of smart technologies and 3D printing, enabling manufacturers to create complex geometries and customize fan configurations to meet specific application needs. These innovations facilitate improved energy efficiency and performance, aligning with the growing demand for sustainable solutions in various industries.

Working Principle

DC axial fans operate based on the principle of converting electrical energy into mechanical energy to generate airflow. When the motor of the fan is activated, it rotates the fan’s shaft, which subsequently drives the blades, creating airflow along the axis of the fan. This process is particularly efficient for generating large volumes of air movement in various applications, including electronic cooling, industrial equipment, and heat dissipation systems.

Airflow Dynamics

The design and geometry of the fan blades play a critical role in influencing the efficiency and performance of DC axial fans. Modern blades are often designed with airfoil shapes that minimize turbulence and resistance, thereby enhancing airflow and reducing noise levels. Factors such as blade pitch and quantity also significantly affect air movement; for instance, a steeper pitch can increase airflow but may contribute to higher noise levels. Innovations in blade construction, including the use of lightweight materials, further optimize airflow dynamics, resulting in better cooling performance and energy efficiency.

Power and Efficiency Considerations

Motor speed is another essential factor impacting airflow generation. Higher motor speeds typically result in increased airflow but can also lead to elevated noise levels. As power demands increase, particularly in high-end applications like server cooling, the efficiency of the fan becomes paramount. Using high-efficiency DC fans allows for more effective heat management while potentially reducing the overall power requirements for cooling systems, as less power is needed to achieve the desired airflow. Additionally, the flexibility of low-voltage power input options makes DC fans suitable for diverse electrical environments, ensuring compatibility across various applications.

Performance Characteristics

DC axial fans are distinguished by several performance characteristics that make them a preferred choice in various applications, particularly where energy efficiency, noise reduction, and durability are paramount.

Advantages and Disadvantages

Advantages of DC Axial Fans

DC axial fans are celebrated for their efficient airflow generation, making them a preferred choice for a wide range of applications. One of the primary advantages is their energy efficiency; these fans can achieve an 80% reduction in energy consumption compared to their AC counterparts, making them environmentally friendly and cost-effective solutions for cooling needs. Their ability to operate at variable speeds allows for customized airflow management, which is particularly beneficial in environments with changing cooling requirements.

Moreover, the versatility of DC axial fans is notable; they are suitable for diverse applications including electronics cooling, automotive systems, telecommunications, industrial automation, and medical devices. The compact design of DC fans addresses space constraints, which is increasingly important in modern engineering where devices need to fit into smaller enclosures without sacrificing performance. Durability is another key advantage; high-quality construction from robust materials extends the lifespan of these fans, reducing the need for frequent replacements and maintenance.

Incorporating IoT technology into DC axial fans also enhances their functionality. Smart fans can offer remote monitoring, predictive maintenance, and valuable performance data, aligning with the growing trend towards smart industrial solutions. Overall, by prioritizing energy-efficient devices like DC axial fans, organizations can significantly reduce operational expenses while contributing to sustainability goals.

Disadvantages of DC Axial Fans

Despite their many benefits, DC axial fans have some drawbacks that engineers must consider. One of the main issues is their performance in relation to static pressure. DC axial fans are generally optimized for low-resistance environments, and in applications requiring high static pressure, centrifugal blowers may be a better choice. Additionally, noise levels can be a concern; while many DC fans operate quietly, certain designs may still generate sound levels that are unacceptable in sensitive environments.

Another consideration is the aerodynamically unstable operating range that some DC axial fans may exhibit near their optimal performance. Fluctuations in system pressure can lead to performance issues, making it crucial for engineers to understand and manage these factors in their designs. Proper installation is also essential; careful attention must be paid to the mounting and airflow direction, particularly in horizontal installations, to avoid condensation issues.

Furthermore, as manufacturers strive to meet higher energy efficiency standards, the competition in the market increases, impacting profitability and pricing strategies. Companies must balance innovation with cost control in a rapidly evolving landscape. Lastly, global supply chain disruptions can affect the availability and cost of materials, posing additional challenges for the production of DC axial fans.

Applications

DC axial fans are utilized across a wide range of industries and applications due to their efficiency and versatility. They play a critical role in maintaining optimal temperature and air quality in various settings, including industrial, commercial, and residential environments.

Comparison with Other Types of Fans

DC axial fans are commonly compared to other fan types, particularly centrifugal fans and radial fans, due to their differing operational characteristics and applications. Understanding these differences is crucial for selecting the right fan type based on specific requirements.

Axial Fans vs. Centrifugal Fans

Design and Airflow

Axial fans feature blades that rotate around an axis, producing airflow that is parallel to the fan axis. This design allows them to generate a high flow rate of air but at relatively low pressure. In contrast, centrifugal fans, also known as radial fans, operate by rotating blades around a central hub, which creates a centrifugal force that pushes air outward. This design results in airflow that is perpendicular to the fan axis, allowing centrifugal fans to produce higher pressures compared to axial fans.

Performance Characteristics

When it comes to pressure capabilities, centrifugal fans are often favored for high-pressure applications, such as in HVAC systems and processes that involve overcoming resistance from long ductwork. Their ability to create higher air pressures makes them more suitable for tasks requiring directed air movement and overcoming significant resistance. Conversely, DC axial fans excel in applications that prioritize airflow and energy efficiency, making them ideal for cooling electronic devices where consistent airflow is essential for thermal management.

Applications

Both axial and centrifugal fans find use in a variety of sectors, including HVAC, dust collection systems, and fume extraction in industrial settings. However, their suitability varies based on the application requirements. For example, axial fans are commonly employed in environments where a high volume of air needs to be moved quietly, while centrifugal fans are preferred in scenarios demanding higher pressure and directed airflow.

Efficiency and Noise Levels

Fan efficiency is becoming an increasingly critical parameter in selection processes, particularly with evolving equipment efficiency standards. DC axial fans are recognized for their high efficiency in cooling applications, boasting features such as variable speeds and low noise levels, making them particularly suitable for sensitive environments like offices and data centers. In contrast, while centrifugal fans can also achieve energy efficiency, they typically require more power to operate, which can impact operational costs in long-term use.

Maintenance and Troubleshooting

Regular Maintenance Strategies

To ensure optimal performance and longevity of DC axial fans, it is essential to adopt a proactive maintenance routine.

- Regular Cleaning: Periodically remove dust and debris from the blades to prevent airflow obstruction, which can significantly impact cooling efficiency.

- Lubrication: Adhere to manufacturer guidelines for lubricating moving parts. Proper lubrication minimizes friction and wear, thereby extending the lifespan of the fan.

- Inspection: Conduct routine inspections for signs of wear or damage. This proactive approach ensures all components are functioning correctly and helps identify potential issues before they escalate.

- Vibration Monitoring: Monitor vibration levels consistently, as excessive vibrations can indicate underlying mechanical problems that require immediate attention.

Troubleshooting Common Issues

Engineers and technicians should be prepared to troubleshoot common issues that may arise with DC axial fans:

- Noise Levels: Axial fans can generate greater noise levels compared to centrifugal models, particularly at increased speeds, with some types exceeding 70 dB during high-speed operations. It is essential to evaluate noise management strategies, especially in sensitive environments.

- Limited Pressure Applications: Axial fans are not designed for high static pressure environments, which can diminish their performance in such conditions. Understanding the limitations of these fans is critical when selecting the appropriate device for specific applications.

- Directional Airflow: While axial fans are efficient at moving air in a single direction, this may not be suitable for all applications, particularly those requiring multi-directional airflow.

Best Practices for Longevity

Implementing best practices can significantly enhance the reliability and performance of DC axial fans:

- Avoid Harsh Chemicals: When cleaning, use gentle solutions that maintain the integrity of the fan components, avoiding aggressive cleaning agents that could cause damage.

- Set a Maintenance Schedule: Establishing a regular maintenance schedule can improve the efficiency and lifespan of ventilation systems in electronic cooling applications.

- Wet Cleaning Techniques: For thorough cleaning, consider using a low-pressure water jet while protecting electrical components and bearings. This method prevents oxidation in the motor by effectively evaporating condensation.

By adhering to these maintenance and troubleshooting guidelines, users can ensure that their DC axial fans operate efficiently and reliably, minimizing downtime and maximizing the performance of the electronic devices they cool.

Future Trends

The DC axial fan market is poised for significant growth, driven by several emerging trends and technological advancements. One of the most critical factors influencing this trajectory is the increasing demand for energy-efficient solutions across various industries, including automotive, telecommunications, and data centers. The market is expected to grow at a compound annual growth rate (CAGR) of 4.1% from 2024 to 2030, highlighting the need for effective cooling solutions in compact and high-performance systems.

Technological Advancements

Innovations such as smart, IoT-enabled fans and brushless DC motors are transforming the landscape of DC axial fans. These advancements are enhancing performance, reducing energy consumption, and enabling features like remote monitoring and control, which facilitate predictive maintenance and optimized operational efficiency. The integration of Industry 4.0 technologies further supports real-time monitoring, contributing to a more intelligent cooling solution environment.

Focus on Sustainability

Sustainability is becoming a pivotal trend, with manufacturers prioritizing eco-friendly materials and processes in their production lines. The use of recyclable materials and efforts to minimize environmental impact align with global environmental goals and consumer preferences for greener products. This focus on sustainability is not only shaping production practices but also influencing product design, as consumers increasingly favor eco-conscious options.

Market Dynamics and Regional Growth

The market is also witnessing substantial growth in emerging economies, particularly in the Asia-Pacific region. Rapid industrialization and urbanization in countries like China and India are driving demand for cooling fans, particularly in sectors such as automotive, consumer electronics, and manufacturing. As industries like data centers and telecommunications expand in these regions, the adoption of DC axial fans for efficient thermal management is on the rise.

Challenges and Competitive Landscape

Despite the promising outlook, the DC axial fan market faces challenges, including intense competition among manufacturers, which can impact profitability and market share. Companies must continually innovate and differentiate their products to navigate these competitive pressures successfully. Additionally, global supply chain disruptions pose risks to material availability and pricing, complicating production schedules and strategies for market players.